|

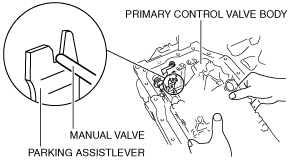

PRIMARY CONTROL VALVE BODY INSTALLATION [FS5A-EL]

id051721807400

On-Vehicle Installation

am6zzw00004922

|

1. Install the accumulator springs and accumulators into the transaxle case.

am6zzw00004923

|

Accumulator spring specification

|

Spring |

Outer diameter (mm {in}) |

Free Length (mm {in}) |

No. of coils |

Wire diameter (mm {in}) |

|---|---|---|---|---|

|

Servo apply accumulator large spring

|

21.0 {0.827}

|

67.8 {2.669}

|

10.3

|

3.5 {0.138}

|

|

Servo apply accumulator small spring

|

13.0 {0.512}

|

67.8 {2.669}

|

17.1

|

2.2 {0.087}

|

|

Forward accumulator large spring

|

21.0 {0.827}

|

75.0 {2.953}

|

10.7

|

2.3 {0.091}

|

|

Forward accumulator small spring

|

15.6 {0.614}

|

49.0 {1.929}

|

7.7

|

2.4 {0.094}

|

2. Tighten the bolts as shown to install the primary control valve body.

am6zzw00004924

|

Bolt length measured from below the head

|

Mark |

Length measured from below the head |

|---|---|

|

B

|

40mm {1.575 in}

|

|

No mark

|

70mm {2.756 in}

|

3. Install the oil strainer.

4. Match the harness colors, then connect each solenoid valves connector and TFT sensor.

Connector color (harness-side)

|

Solenoid valve |

Connector color |

|---|---|

|

Pressure control solenoid A

|

Black

|

|

Shift solenoid A

|

White

|

|

Shift solenoid B

|

Blue

|

|

Shift solenoid C

|

Green

|

|

Shift solenoid D

|

White

|

|

Shift solenoid E

|

Black

|

5. Install the GND.

am6zzw00006080

|

6. Apply a light coat of silicon sealant (TB1217E) to the contact surfaces of the oil pan and transaxle case.

am6zzw00004926

|

7. Install the oil pan before the applied sealant starts to harden.

8. Install the front crossmember. (See FRONT CROSSMEMBER REMOVAL/INSTALLATION.)

9. Add the ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [FS5A-EL].)

10. Install the aerodynamic under cover NO.2. (See AERODYNAMIC UNDER COVER NO.2 REMOVAL/INSTALLATION.)

11. Connect the negative battery cable.

12. Perform the “Mechanical System Test”. (See MECHANICAL SYSTEM TEST [FS5A-EL].)

13. Perform the “Road Test”. (See ROAD TEST [FS5A-EL].)