|

DTC P02CA:00 [PCM (SKYACTIV-D 2.2)]

id0102j5212200

Engine Type

|

Item |

Reference |

|---|---|

|

Fuel injector (6 pin type), without SCR System

|

|

|

Fuel injector (6 pin type), with SCR System

|

Fuel Injector (6 pin type), Without SCR System

Details on DTCs

|

System malfunction location |

Large-type turbocharger area control system: Overboost |

|

|---|---|---|

|

Detection condition

|

Determination condition

|

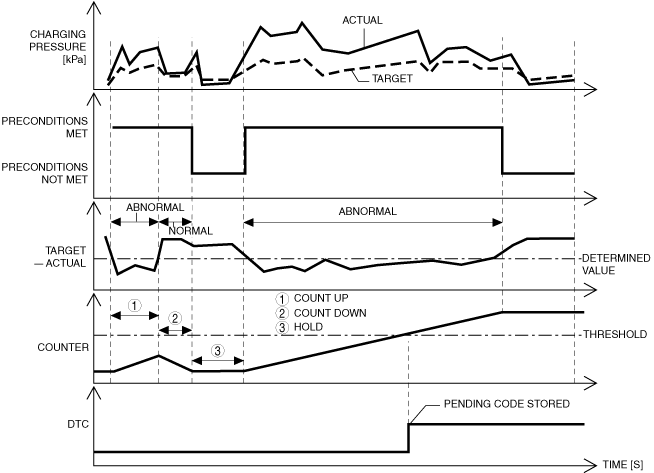

• As the result of comparing the actual boost pressure with the target boost pressure, the actual boost pressure exceeds the specification higher than the target boost pressure for a continuous 7 s.

|

|

Preconditions

|

• All of the following conditions are met when diesel particulate filter regeneration control is stopped during boost control feedback

|

|

|

Drive cycle

|

• 2

|

|

|

Self-test type

|

• CMDTC self test

|

|

|

Sensor/unit used

|

• MAP sensor

|

|

|

Fail-safe

|

• Not applicable

|

|

|

Vehicle status when DTCs are output

|

• Not applicable

|

|

|

Possible cause

|

• PCM input signal error

• Malfunction in vacuum piping and positive pressure piping of compressor bypass solenoid valve

• Regulating valve actuator malfunction

• Variable turbine geometry turbocharger actuator malfunction

• Compressor bypass solenoid valve malfunction

• Regulating valve actuator position sensor malfunction

• Variable turbine geometry turbocharger actuator position sensor malfunction

• PCM malfunction

|

|

System Wiring Diagram

Function Explanation (DTC Detection Outline)

ac5wzw00012276

|

Repeatability Verification Procedure

PID Item/Simulation Item Used in Diagnosis

PID

|

Item name |

Outline |

Unit |

Display/condition |

|---|---|---|---|

|

INTK_MAPA

|

Manifold absolute pressure (No.2)

|

kPa

|

• Displays the manifold absolute pressure (No.2).

|

|

MAP_DSD

|

Manifold absolute pressure (No.2) desired value

|

kPa

|

• Displays the manifold absolute pressure (No.2) desired value.

|

|

REGVP

|

Regulating valve actuator position

|

mm

|

• Displays the regulating valve actuator position.

|

|

REGVP_DSD

|

Target value for regulating valve actuator position sensor

|

mm

|

• Displays the target value for the regulating valve actuator position.

|

|

VGTURB_ACT

|

Variable turbine geometry turbocharger actuator position

|

%

|

• Displays the variable turbine geometry turbocharger actuator position.

|

Simulation item

|

Item name |

Outline |

Unit |

Display/condition |

|---|---|---|---|

|

VGTURB_DSD

|

Variable turbine geometry turbocharger actuator position

|

%

|

• Changes % and forcibly drives/stops the variable turbine geometry turbocharger actuator.

|

Function Inspection Using M-MDS

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

PURPOSE: VERIFY DTC CAUSING FREEZE FRAME DATA

• Is DTC P02CA:00 causing the freeze frame data?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect the DTC causing the freeze frame data.

|

||

|

2

|

PURPOSE: RECORD VEHICLE STATUS AT TIME OF DTC DETECTION TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the freeze frame data/snap shot data.

|

―

|

Go to the next step.

|

|

3

|

PURPOSE: VERIFY OTHER RELATED DTCs

• Switch the ignition OFF, and then switch it ON (engine off).

• Display the DTCs using the M-MDS.

• Has any DTC other than P02CA:00 been stored?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

||

|

4

|

PURPOSE: VERIFY MAP SENSOR INPUT SIGNAL

• Start the engine and warm it up.

• Display the following PIDs using the M-MDS.

• Are the monitoring values normal?

|

Yes

|

Go to the troubleshooting procedure to perform the procedure from Step 1.

|

|

No

|

Go to the next step.

|

||

|

5

|

PURPOSE: INSPECT WIRING HARNESSES AND CONNECTORS FOR RELATED-SENSOR

• Display the following PIDs using the M-MDS.

• When the PCM and MAP sensor connector are shaken, does the PID value include a PID item which has changed?

|

Yes

|

Inspect the related wiring harnesses and connectors.

• Repair or replace the malfunctioning location.

Go to the troubleshooting procedure to perform the procedure from Step 5.

|

|

No

|

Go to the troubleshooting procedure to perform the procedure from Step 1.

|

||

|

6

|

PURPOSE: DETERMINE IF MALFUNCTION IS CAUSED BY REGULATING VALVE ACTUATOR POSITION SENSOR MALFUNCTION

• Inspect the regulating valve actuator position sensor.

• Is the regulating valve actuator position sensor normal?

|

Yes

|

Go to the troubleshooting procedure to perform the procedure from Step 1.

|

|

No

|

Inspect the related wiring harnesses and connectors.

• Repair or replace the malfunctioning location.

Go to the troubleshooting procedure to perform the procedure from Step 5.

|

||

|

7

|

PURPOSE: DETERMINE IF MALFUNCTION IS CAUSED BY VARIABLE TURBINE GEOMETRY TURBOCHARGER ACTUATOR POSITION SENSOR MALFUNCTION

• Inspect the variable turbine geometry turbocharger actuator position sensor.

• Is the variable turbine geometry turbocharger actuator position sensor normal?

|

Yes

|

Go to the troubleshooting procedure to perform the procedure from Step 1.

|

|

No

|

Inspect the related wiring harnesses and connectors.

• Repair or replace the malfunctioning location.

Go to the troubleshooting procedure to perform the procedure from Step 5.

|

Troubleshooting Diagnostic Procedure

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

PURPOSE: INSPECT VACUUM PIPING AND POSITIVE PRESSURE PIPING OF COMPRESSOR BYPASS SOLENOID VALVE

• Inspect the vacuum piping and positive pressure piping of the compressor bypass solenoid valve.

• Is there hose leakage or damage in the vacuum piping and positive pressure piping?

|

Yes

|

Repair or replace the malfunctioning location, then go to Step 5.

|

|

No

|

Go to the next step.

|

||

|

2

|

PURPOSE: INSPECT COMPRESSOR BYPASS SOLENOID VALVE

• Inspect the compressor bypass solenoid valve.

• Is the compressor bypass solenoid valve normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the compressor bypass solenoid valve, then go to Step 5.

|

||

|

3

|

PURPOSE: INSPECT REGULATING VALVE ACTUATOR

• Inspect the regulating valve actuator.

• Is the regulating valve actuator normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the regulating valve actuator, then go to Step 5.

|

||

|

4

|

PURPOSE: INSPECT VARIABLE TURBINE GEOMETRY TURBOCHARGER ACTUATOR

• Inspect the variable turbine geometry turbocharger actuator.

• Is the variable turbine geometry turbocharger actuator normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the variable turbine geometry turbocharger actuator, then go to Step 5.

|

||

|

5

|

PURPOSE: VERIFICATION OF VEHICLE REPAIR COMPLETION

• Reconnect all disconnected connectors and hoses.

• Refer to the [MEMORY CLEARING PROCEDURE] and clear the DTC.

• Implement the repeatability verification procedure.

• Display the DTCs using the M-MDS.

• Is DTC P02CA:00 displayed?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the PCM, then go to the next step.

|

|

No

|

Go to the next step.

|

||

|

6

|

PURPOSE: VERIFY IF THERE IS ANY OTHER MALFUNCTION

• Has any other DTC or pending code been stored?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|

Fuel Injector (6 pin type), With SCR System

Details on DTCs

|

System malfunction location |

Large-type turbocharger area control system: Overboost |

|

|---|---|---|

|

Detection condition

|

Determination condition

|

• As the result of comparing the actual boost pressure with the target boost pressure, the actual boost pressure exceeds the specification higher than the target boost pressure for a continuous 7 s.

|

|

Preconditions

|

• All of the following conditions are met when diesel particulate filter regeneration control is stopped during boost control feedback

|

|

|

Drive cycle

|

• 2

|

|

|

Self-test type

|

• CMDTC self test

|

|

|

Sensor/unit used

|

• MAP sensor

|

|

|

Fail-safe

|

• Not applicable

|

|

|

Vehicle status when DTCs are output

|

• Not applicable

|

|

|

Possible cause

|

• PCM input signal error

• Malfunction in vacuum piping and positive pressure piping of compressor bypass solenoid valve

• Regulating valve actuator malfunction

• Variable turbine geometry turbocharger actuator malfunction

• Compressor bypass solenoid valve malfunction

• Regulating valve actuator position sensor malfunction

• Variable turbine geometry turbocharger actuator position sensor malfunction

• PCM malfunction

|

|

System Wiring Diagram

Function Explanation (DTC Detection Outline)

am6zzw00014396

|

Repeatability Verification Procedure

PID Item/Simulation Item Used in Diagnosis

PID

|

Item name |

Outline |

Unit |

Display/condition |

|---|---|---|---|

|

INTK_MAPA

|

Manifold absolute pressure (No.2)

|

kPa

|

• Displays the manifold absolute pressure (No.2).

|

|

MAP_DSD

|

Manifold absolute pressure (No.2) desired value

|

kPa

|

• Displays the manifold absolute pressure (No.2) desired value.

|

|

REGVP

|

Regulating valve actuator position

|

mm

|

• Displays the regulating valve actuator position.

|

|

REGVP_DSD

|

Target value for regulating valve actuator position sensor

|

mm

|

• Displays the target value for the regulating valve actuator position.

|

|

VGTURB_ACT

|

Variable turbine geometry turbocharger actuator position

|

%

|

• Displays the variable turbine geometry turbocharger actuator position.

|

Simulation item

|

Item name |

Outline |

Unit |

Display/condition |

|---|---|---|---|

|

VGTURB_DSD

|

Variable turbine geometry turbocharger actuator position

|

%

|

• Changes % and forcibly drives/stops the variable turbine geometry turbocharger actuator.

|

Function Inspection Using M-MDS

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

PURPOSE: VERIFY DTC CAUSING FREEZE FRAME DATA

• Is DTC P02CA:00 causing the freeze frame data?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect the DTC causing the freeze frame data.

|

||

|

2

|

PURPOSE: RECORD VEHICLE STATUS AT TIME OF DTC DETECTION TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the freeze frame data/snap shot data.

|

―

|

Go to the next step.

|

|

3

|

PURPOSE: VERIFY OTHER RELATED DTCs

• Switch the ignition OFF, and then switch it ON (engine off).

• Display the DTCs using the M-MDS.

• Has any DTC other than P02CA:00 been stored?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

||

|

4

|

PURPOSE: VERIFY MAP SENSOR INPUT SIGNAL

• Start the engine and warm it up.

• Display the following PIDs using the M-MDS.

• Are the monitoring values normal?

|

Yes

|

Go to Troubleshooting Diagnostic Procedure to perform the procedure from step 1.

|

|

No

|

Go to the next step.

|

||

|

5

|

PURPOSE: INSPECT WIRING HARNESSES AND CONNECTORS FOR RELATED-SENSOR

• Display the following PIDs using the M-MDS.

• When the PCM and MAP sensor connector are shaken, does the PID value include a PID item which has changed?

|

Yes

|

Inspect the related wiring harnesses and connectors.

• Repair or replace the malfunctioning location.

Go to Troubleshooting Diagnostic Procedure to perform the procedure from step 5.

|

|

No

|

Go to Troubleshooting Diagnostic Procedure to perform the procedure from step 1.

|

||

|

6

|

PURPOSE: DETERMINE IF MALFUNCTION IS CAUSED BY REGULATING VALVE ACTUATOR POSITION SENSOR MALFUNCTION

• Inspect the regulating valve actuator position sensor.

• Is the regulating valve actuator position sensor normal?

|

Yes

|

Go to Troubleshooting Diagnostic Procedure to perform the procedure from step 1.

|

|

No

|

Inspect the related wiring harnesses and connectors.

• Repair or replace the malfunctioning location.

Go to Troubleshooting Diagnostic Procedure to perform the procedure from step 5.

|

||

|

7

|

PURPOSE: DETERMINE IF MALFUNCTION IS CAUSED BY VARIABLE TURBINE GEOMETRY TURBOCHARGER ACTUATOR POSITION SENSOR MALFUNCTION

• Inspect the variable turbine geometry turbocharger actuator position sensor.

• Is the variable turbine geometry turbocharger actuator position sensor normal?

|

Yes

|

Go to Troubleshooting Diagnostic Procedure to perform the procedure from step 1.

|

|

No

|

Inspect the related wiring harnesses and connectors.

• Repair or replace the malfunctioning location.

Go to Troubleshooting Diagnostic Procedure to perform the procedure from step 5.

|

Troubleshooting Diagnostic Procedure

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

PURPOSE: INSPECT VACUUM PIPING AND POSITIVE PRESSURE PIPING OF COMPRESSOR BYPASS SOLENOID VALVE

• Inspect the vacuum piping and positive pressure piping of the compressor bypass solenoid valve.

• Is there hose leakage or damage in the vacuum piping and positive pressure piping?

|

Yes

|

Repair or replace the malfunctioning location, then go to Step 5.

|

|

No

|

Go to the next step.

|

||

|

2

|

PURPOSE: INSPECT COMPRESSOR BYPASS SOLENOID VALVE

• Inspect the compressor bypass solenoid valve.

• Is the compressor bypass solenoid valve normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the compressor bypass solenoid valve, then go to Step 5.

|

||

|

3

|

PURPOSE: INSPECT REGULATING VALVE ACTUATOR

• Inspect the regulating valve actuator.

• Is the regulating valve actuator normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the regulating valve actuator, then go to Step 5.

|

||

|

4

|

PURPOSE: INSPECT VARIABLE TURBINE GEOMETRY TURBOCHARGER ACTUATOR

• Inspect the variable turbine geometry turbocharger actuator.

• Is the variable turbine geometry turbocharger actuator normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the variable turbine geometry turbocharger actuator, then go to Step 5.

|

||

|

5

|

PURPOSE: VERIFICATION OF VEHICLE REPAIR COMPLETION

• Reconnect all disconnected connectors and hoses.

• Refer to the [MEMORY CLEARING PROCEDURE] and clear the DTC.

• Implement the repeatability verification procedure.

• Display the DTCs using the M-MDS.

• Is DTC P02CA:00 displayed?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the PCM, then go to the next step.

|

|

No

|

Go to the next step.

|

||

|

6

|

PURPOSE: VERIFY IF THERE IS ANY OTHER MALFUNCTION

• Has any other DTC or pending code been stored?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|