|

OIL PRESSURE SWITCH REMOVAL/INSTALLATION [FW6A-EL]

id0517h1112600

Oil Pressure Switch A

1. Select the selector lever to P position.

2. Disconnect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL DISCONNECTION/CONNECTION.)

3. Remove the plug hole plate. (See PLUG HOLE PLATE REMOVAL/INSTALLATION [SKYACTIV-G 2.0, SKYACTIV-G 2.5 (WITHOUT CYLINDER DEACTIVATION)].) (See PLUG HOLE PLATE REMOVAL/INSTALLATION [SKYACTIV-G 2.5 (WITH CYLINDER DEACTIVATION)].)

4. Remove the front under cover No.2. (See FRONT UNDER COVER No.2 REMOVAL/INSTALLATION.)

5. Clean the transaxle exterior throughout with a steam cleaner or cleaning solvents.

6. Remove the following parts as a single unit. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [SKYACTIV-G 2.0, SKYACTIV-G 2.5 (WITHOUT CYLINDER DEACTIVATION)].) (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [SKYACTIV-G 2.5 (WITH CYLINDER DEACTIVATION)].)

7. Drain the ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [FW6A-EL].)

8. Remove the oil pan.

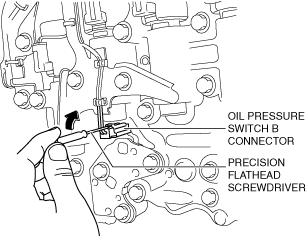

9. Insert a precision flathead screwdriver and move it in the direction of the arrow to disconnect the oil pressure switch A connector as shown in the figure.

am6zzw00017952

|

10. Remove the oil pressure switch A fitting bolts.

ac5uuw00000198

|

11. Insert a flathead screwdriver as shown in the figure and remove oil pressure switch A from the control valve body while avoiding contact with the oil pan installation surface.

am6zzw00018321

|

12. Install the oil pressure switch A to the control valve body.

13. Install the oil pressure switch A fitting bolts.

ac5uuw00000198

|

14. Connect the oil pressure switch A connector.

ac5uuw00000200

|

15. Apply a light coat of silicone sealant (TB1217E or equivalent) to the contact surfaces of the oil pan and transaxle case.

am3uuw00008281

|

16. Install the oil pan with new bolts before the applied sealant starts to harden.

ac5uuw00003246

|

17. Add the ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [FW6A-EL].)

18. Install the following parts as a single unit. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [SKYACTIV-G 2.0, SKYACTIV-G 2.5 (WITHOUT CYLINDER DEACTIVATION)].) (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [SKYACTIV-G 2.5 (WITH CYLINDER DEACTIVATION)].)

19. Install the plug hole plate. (See PLUG HOLE PLATE REMOVAL/INSTALLATION [SKYACTIV-G 2.0, SKYACTIV-G 2.5 (WITHOUT CYLINDER DEACTIVATION)].) (See PLUG HOLE PLATE REMOVAL/INSTALLATION [SKYACTIV-G 2.5 (WITH CYLINDER DEACTIVATION)].)

20. Connect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL DISCONNECTION/CONNECTION.)

21. Perform the “Initial Learning” (Oil pressure switch A replacement). (See INITIAL LEARNING [FW6A-EL].)

22. Perform the “Mechanical System Test”. (See MECHANICAL SYSTEM TEST [FW6A-EL].)

Oil Pressure Switch B

1. Disconnect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL DISCONNECTION/CONNECTION.)

2. Remove the front under cover No.2. (See FRONT UNDER COVER No.2 REMOVAL/INSTALLATION.)

3. Clean the transaxle exterior throughout with a steam cleaner or cleaning solvents.

4. Drain the ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [FW6A-EL].)

5. Remove the oil pan.

6. Remove the oil strainer. (See CONTROL VALVE BODY REMOVAL/INSTALLATION [FW6A-EL].)

7. Remove the oil strainer O-ring. (See CONTROL VALVE BODY REMOVAL/INSTALLATION [FW6A-EL].)

8. Insert a precision flathead screwdriver and move it in the direction of the arrow to disconnect the oil pressure switch B connector as shown in the figure.

am6zzw00017952

|

9. Remove the oil pressure switch B.

ac5uuw00000201

|

10. Install the oil pressure switch B.

ac5uuw00000201

|

11. Connect the oil pressure switch B connector.

am3uuw00008721

|

12. Install the new oil strainer O-ring. (See CONTROL VALVE BODY REMOVAL/INSTALLATION [FW6A-EL].)

13. Install the new oil strainer. (See CONTROL VALVE BODY REMOVAL/INSTALLATION [FW6A-EL].)

14. Apply a light coat of silicone sealant (TB1217E or equivalent) to the contact surfaces of the oil pan and transaxle case.

am3uuw00008281

|

15. Install the oil pan with new bolts before the applied sealant starts to harden.

ac5uuw00003246

|

16. Install the front under cover No.2. (See FRONT UNDER COVER No.2 REMOVAL/INSTALLATION.)

17. Add the ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [FW6A-EL].)

18. Connect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL DISCONNECTION/CONNECTION.)

19. Perform the “Initial Learning” (Oil pressure switch B replacement). (See INITIAL LEARNING [FW6A-EL].)

20. Perform the “Mechanical System Test”. (See MECHANICAL SYSTEM TEST [FW6A-EL].)