|

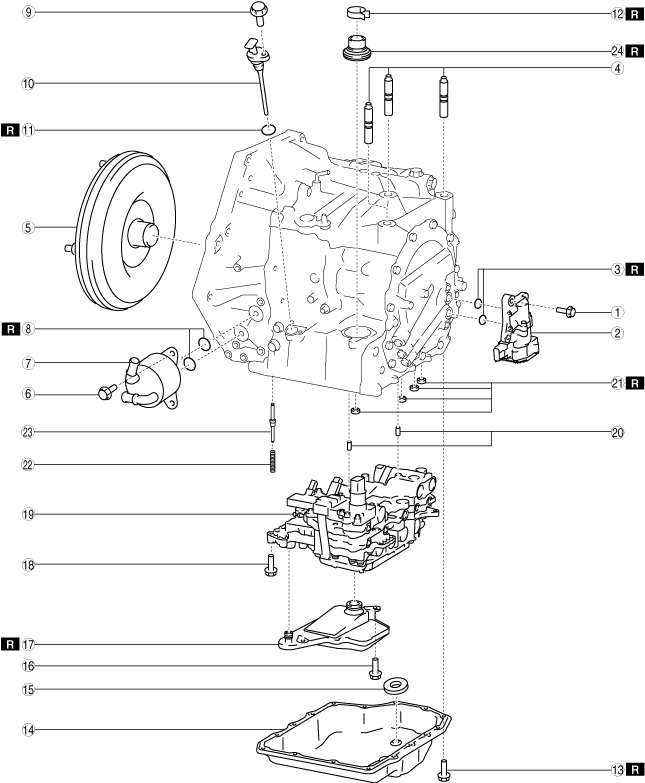

AUTOMATIC TRANSAXLE DISASSEMBLY

id051700660600

Structural View

Automatic transaxle 1

bgw2za00000152

|

|

1

|

3 bolts*1

|

|

2

|

Electric AT oil pump*1

|

|

3

|

O-ring*1

|

|

4

|

Stud bolt

|

|

5

|

Torque converter

|

|

6

|

3 bolts

|

|

7

|

Oil cooler

|

|

8

|

O-ring

|

|

9

|

Bolt

|

|

10

|

Dipstick

|

|

11

|

O-ring

|

|

12

|

Hose clamp

|

|

13

|

16 bolts

|

|

14

|

Oil pan

|

|

15

|

Magnet

|

|

16

|

2 bolts

|

|

17

|

Oil strainer

|

|

18

|

11 bolts

|

|

19

|

Control valve body

|

|

20

|

Dowel pin

|

|

21

|

Gasket

|

|

22

|

Spool valve spring*2

|

|

23

|

Spool valve*2

|

|

24

|

Oil seal

|

Automatic transaxle 2

bgw2za00000120

|

|

1

|

25 bolts

|

|

2

|

Converter housing

|

|

3

|

O-ring

|

|

4

|

O-ring

|

|

5

|

3 bolts

|

|

6

|

Baffle plate

|

|

7

|

Oil seal

|

|

8

|

Bearing race

|

|

9

|

Shim

|

|

10

|

Bearing race

|

|

11

|

Shim

|

Automatic transaxle 3

bgw2za00000153

|

|

1

|

Baffle plate

|

|

2

|

7 bolts

|

|

3

|

Oil pump

|

|

4

|

Thrust needle bearing

|

|

5

|

High clutch component and low clutch component

|

|

6

|

Turbine shaft

|

|

7

|

D-ring

|

|

8

|

Seal ring

|

|

9

|

Thrust needle bearing

|

|

10

|

High clutch hub

|

|

11

|

Thrust needle bearing

|

|

12

|

Low clutch hub

|

|

13

|

Thrust needle bearing

|

|

14

|

Ring gear and differential

|

|

15

|

Oil pipe

|

|

16

|

Secondary gear and output gear

|

|

17

|

2 bolts

|

|

18

|

Baffle plate

|

|

19

|

Oil seal

|

|

20

|

Bearing race

|

|

21

|

Shim

|

|

22

|

Bearing race

|

Automatic transaxle 4

bgw2za00000154

|

|

1

|

12 bolts

|

|

2

|

End cover component

|

|

3

|

O-ring

|

|

4

|

Shim

|

|

5

|

Thrust needle bearing

|

|

6

|

Reduction sun gear

|

|

7

|

Thrust needle bearing

|

|

8

|

Rear planetary gear

|

|

9

|

Rear sun gear

|

|

10

|

Front sun gear

|

|

11

|

Locknut

|

|

12

|

Front planetary gear

|

|

13

|

Snap ring

|

|

14

|

One-way clutch

|

|

15

|

Drive plate

|

|

16

|

Driven plate

|

|

17

|

Springs and retainer component

|

|

18

|

Low and reverse brake piston

|

Automatic transaxle 5

bgw2za00000155

|

|

1

|

Connector

|

|

2

|

Gasket

|

|

3

|

Gasket

|

|

4

|

Oil pipe

|

|

5

|

O-ring

|

|

6

|

2 bolts

|

|

7

|

Detent bracket component

|

|

8

|

Pawl return spring

|

|

9

|

Support actuator

|

|

10

|

Parking pawl pin

|

|

11

|

Parking rod component

|

|

12

|

Plug

|

|

13

|

Gasket

|

|

14

|

Parking pawl shaft

|

|

15

|

Parking pawl

|

|

16

|

Roll pin

|

|

17

|

Parking shift lever component

|

|

18

|

Parking assist lever component

|

|

19

|

Manual plate component

|

|

20

|

Oil seal

|

|

21

|

Washer

|

|

22

|

Connector bolt *

|

|

23

|

Gasket *

|

Automatic transaxle 6

bgw2za00000156

|

|

1

|

Primary gear

|

|

2

|

Angular contact ball bearing

|

|

3

|

Plug

|

|

4

|

Gasket

|

|

5

|

Transaxle case

|

Disassembly Procedure

1. Clean the outside of the transaxle. (See AUTOMATIC TRANSAXLE CLEANING.)

2. Remove the electric AT oil pump using the following procedure (only vehicles with i-stop).

bgw2za00000157

|

|

1

|

3 bolts

|

|

2

|

Electric AT oil pump

|

|

3

|

O-ring

|

bgw3ja00000101

|

bgw3ja00000102

|

bgw3ja00000103

|

bgw2za00000158

|

3. Remove the stud bolts.

bgw3ja00000105

|

4. Remove the torque converter.

bgw3ja00000106

|

5. Remove the oil cooler in the order shown in the figure.

bgw2za00000159

|

|

1

|

Bolt

|

|

2

|

Oil cooler

|

|

3

|

O-ring

|

6. Remove the dipstick in the order shown in the figure.

bgw2za00000160

|

|

1

|

Bolt

|

|

2

|

Dipstick

|

|

3

|

O-ring

|

7. Remove the hose clamp.

bgw2za00000161

|

8. Install the transaxle to the SST (engine stand) using the following procedure:

bgw2za00000162

|

bgw2za00000163

|

bgw2za00000164

|

bgw2za00000165

|

bgw2za00000166

|

bgw2za00000167

|

bgw2za00000168

|

9. Remove the oil pan and magnet using the following procedure:

bgw2za00000169

|

|

1

|

16 bolts

|

|

2

|

Oil pan

|

|

3

|

Magnet

|

azzjjw00000423

|

azzjjw00000424

|

bgw3ja00000118

|

azzjjw00000426

|

10. Remove the oil strainer in the order shown in the figure.

bgw2za00000170

|

|

1

|

Bolt

|

|

2

|

Oil strainer

|

11. Remove the control valve body using the following procedure:

bgw2za00000171

|

|

1

|

11 bolts

|

|

2

|

Control valve body

|

|

3

|

Dowel pin

|

|

4

|

Gasket

|

|

5

|

Spool valve spring*

|

|

6

|

Spool valve*

|

azzjjw00000429

|

bgw3ja00000121

|

azzjjw00000431

|

bgw3ja00000122

|

bgw2za00000172

|

bgw3ja00000124

|

bgw3ja00000125

|

12. Remove the oil seal.

bgw2za00000173

|

13. Remove the converter housing using the following procedure:

bgw2za00000174

|

|

1

|

25 bolts

|

|

2

|

Converter housing

|

|

3

|

O-ring (oil pump)

|

|

4

|

O-ring (oil cooler oil passage)

|

bgw3ja00000128

|

bgw3ja00000129

|

bgw3ja00000130

|

bgw3ja00000131

|

bgw2za00000175

|

14. Remove the accessories from the converter housing using the following procedure:

bgw3ja00000133

|

|

1

|

Bolt

|

|

2

|

Baffle plate

|

bgw2za00000176

|

bgw3ja00000135

|

bgw2za00000177

|

|

1

|

Bearing race

|

|

2

|

Shim

|

bgw2za00000178

|

bgw2za00000179

|

bgw2za00000180

|

|

1

|

Bearing race

|

|

2

|

Shim

|

bgw2za00000178

|

15. Remove the baffle plate.

bgw3ja00000140

|

16. Remove the oil pump using the following procedure:

bgw3ja00000141

|

|

1

|

7 bolts

|

|

2

|

Oil pump

|

bgw3ja00000142

|

bgw3ja00000143

|

17. Remove the thrust needle bearing.

bgw3ja00000144

|

18. Remove the high clutch component and low clutch component.

bgw3ja00000145

|

19. Remove the turbine shaft.

bgw3ja00000146

|

20. Remove the D-ring and seal rings from the turbine shaft using the procedure in the figure:

bgw2za00000181

|

|

1

|

D-ring

|

|

2

|

Seal ring

|

21. Remove the thrust needle bearing.

bgw3ja00000147

|

22. Remove the high clutch hub.

bgw3ja00000148

|

23. Remove the thrust needle bearing.

bgw3ja00000149

|

24. Remove the low clutch hub.

bgw3ja00000150

|

25. Remove the thrust needle bearing.

bgw3ja00000151

|

26. Remove the ring gear and differential.

bgw3ja00000152

|

27. Remove the oil pipe.

bgw3ja00000153

|

28. Remove the secondary gear and output gear.

bgw3ja00000154

|

29. Remove the baffle plate using the procedure shown in the figure.

bgw2za00000182

|

|

1

|

Bolt

|

|

2

|

Baffle plate

|

30. Remove the oil seal.

bgw2za00000183

|

31. Remove the bearing race and shim using the following procedure:

azzjjw00000465

|

bgw3ja00000156

|

bgw2za00000184

|

|

1

|

Bearing race

|

|

2

|

Shim

|

32. Remove the bearing race using the SST.

bgw3ja00000158

|

bgw3ja00000159

|

33. Remove end cover component using the following procedure:

bgw2za00000185

|

|

1

|

12 bolts

|

|

2

|

End cover component

|

|

3

|

O-ring

|

bgw3ja00000160

|

bgw3ja00000161

|

azzjjw00000473

|

bgw3ja00000162

|

bgw2za00000208

|

34. Remove the shim.

bgw3ja00000164

|

35. Remove the thrust needle bearing.

bgw3ja00000165

|

36. Remove the reduction sun gear.

bgw3ja00000166

|

37. Remove the thrust needle bearing.

bgw3ja00000167

|

38. Remove the rear planetary gear.

bgw3ja00000168

|

39. Remove the rear sun gear.

bgw3ja00000169

|

40. Remove the front sun gear.

bgw3ja00000170

|

41. Inspect the transaxle case, primary gear, and the angular contact ball bearing using the following procedure:

bgw3ja00000171

|

42. Remove the locknut using the following procedure:

bgw3ja00000172

|

bgw2za00000186

|

bgw2za00000187

|

azzjjw00000487

|

bgw2za00000186

|

bgw2za00000188

|

43. Remove the front planetary gear.

bgw3ja00000176

|

44. Perform a simple inspection of the low and reverse brake using the following procedure:

azzjjw00000490

|

45. Remove the snap ring using the following procedure:

bgw2za00000189

|

bgw2za00000190

|

bgw2za00000191

|

bgw3ja00000180

|

bgw2za00000192

|

bgw2za00000189

|

46. Remove the one-way clutch.

azzjjw00000496

|

47. Remove the drive plates and driven plates.

bgw3ja00000182

|

48. Remove the springs and retainer component.

azzjjw00000498

|

49. Remove the low and reverse brake piston using the following procedure:

azzjjw00000499

|

azzjjw00000500

|

50. Remove the connector, gaskets, oil pipe, and the O-rings in the order shown in the figure.

bgw2za00000193

|

|

1

|

Connector

|

|

2

|

Gasket

|

|

3

|

Oil pipe

|

|

4

|

O-ring

|

51. Remove the detent bracket component in the order shown in the figure.

bgw3ja00000184

|

|

1

|

Bolt

|

|

2

|

Detent bracket component

|

52. Remove the pawl return springs.

bgw3ja00000185

|

53. Remove the support actuator.

bgw3ja00000186

|

54. Remove the parking pawl pin.

bgw3ja00000187

|

55. Remove the parking rod component using the following procedure:

bgw3ja00000188

|

bgw3ja00000189

|

56. Remove the parking pawl shaft in the order shown in the figure.

bgw2za00000194

|

|

1

|

Plug

|

|

2

|

Gasket

|

|

3

|

Parking pawl shaft

|

57. Remove the parking pawl.

bgw3ja00000190

|

58. Remove the roll pins shown in the figure using a pin punch.

bgw3ja00000191

|

bgw3ja00000192

|

59. Remove the parking shift lever component.

azzjjw00000512

|

60. Remove the parking assist lever component.

bgw3ja00000193

|

61. Remove the manual plate component.

bgw3ja00000194

|

62. Remove the oil seal.

bgw2za00000195

|

63. Remove the washer.

azzjjw00000516

|

64. Remove the connector bolts and gaskets using the procedure shown in the figure (only vehicles with oil cooler No.2).

bgw2za00000196

|

|

1

|

Connector bolt

|

|

2

|

Gasket

|

65. Perform the following procedure only if there is a malfunction found in the Step 41 inspection.

azzjjw00000465

|

bgw2za00000197

|

bgw3ja00000196

|

azzjjw00001205

|

azzjjw00001206

|

bgw2za00000198

|

bgw2za00000199

|

azzjjw00001208

|

azzjjw00000917

|

|

1

|

Plug

|

|

2

|

Gasket

|

66. Remove the SST from the transaxle case using the following procedure:

azzjjw00000521

|

bgw2za00000200

|

bgw2za00000201

|

bgw2za00000202

|

67. Disassemble the parts in the following order.

68. Clean away the remaining silicone sealant on the transaxle case, converter housing, end cover, oil pan, and the electric AT oil pump*.

69. Clean the disassembled parts. (See AUTOMATIC TRANSAXLE CLEANING.)

70. Perform the following inspection and replace a malfunctioning part with a new one.