|

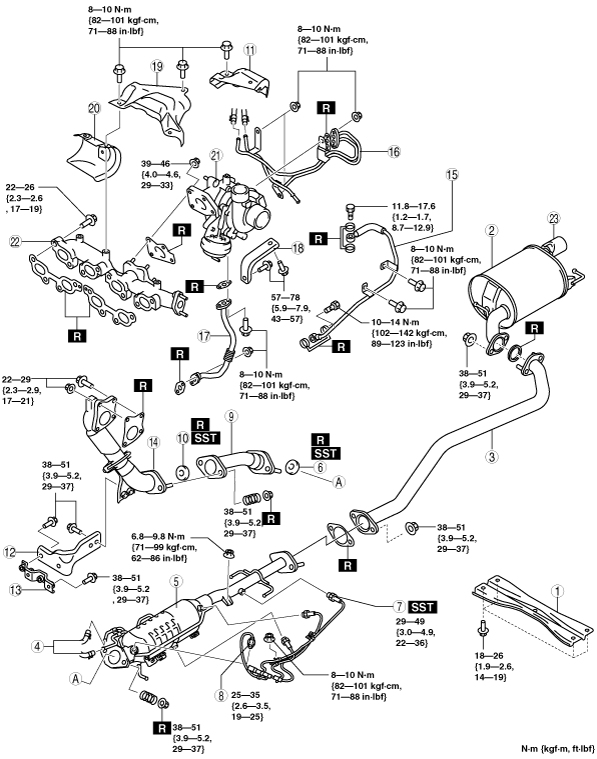

EXHAUST SYSTEM REMOVAL/INSTALLATION [MZR-CD (RF Turbo)]

id0115f1800200

|

STEP |

ACTION |

PAGE/CONDITION |

|---|---|---|

|

1

|

Replace the oxidation catalytic converter.

|

–

|

|

2

|

Switch the ignition to on.

|

–

|

|

3

|

Perform diesel particulate filter data reset procedure.

|

|

|

4

|

Start the engine.

|

Verify that the MIL does not illuminate.

|

|

5

|

Switch the ignition to off.

|

–

|

|

6

|

Switch the ignition to on (Engine off).

|

–

|

|

7

|

Perform KOEO self-test procedure.

|

|

|

8

|

Perform exhaust gas pressure sensor data reset procedure.

|

|

|

9

|

Switch the ignition to off.

|

–

|

|

10

|

Wait for 20 s.

|

–

|

|

11

|

Start the engine.

|

–

|

|

12

|

Perform KOER self-test procedure.

|

Warm up until the exhaust gas temperature (EXHTEMP1, EXHTEMP2, EXHTEMP3 PID) is 100 °C {212 °F} or more.

|

|

13

|

Perform fuel injector injection amount correction procedure.

|

Engine coolant temperature 65—95 °C {149—203 °F}.

Intake air temperature 15—65 °C {59—149 °F}.

Fuel temperature 30—60 °C {86—140 °F}.

|

|

14

|

Perform diesel particulate filter assessment procedure.

|

Engine coolant temperature 60 °C {140 °F} or more.

|

|

15

|

Perform diesel particulate filter regeneration procedure.

|

Engine coolant temperature 70 °C {158 °F} or more.

|

|

16

|

Using the following PIDs, verify that the diesel particulate filter regeneration has been completed.

― REG_REQ_A

― REG_REQ_F

|

|

|

17

|

Perform after repair procedure.

|

|

|

18

|

Switch the ignition to off.

|

–

|

1. Disconnect the negative battery cable. (See BATTERY REMOVAL/INSTALLATION [MZR-CD (RF Turbo)].)

2. Remove the engine cover.

3. Remove in the order indicated in the table.

4. Remove the insulator. (See Exhaust System Insulator Removal/installation Note.)

5. Install in the reverse order of removal.

6. Start the engine and:

am6zzw00003751

|

|

1

|

Tunnel member

|

|

2

|

Main silencer

|

|

3

|

Middle pipe

|

|

4

|

Exhaust gas pressure hose

|

|

5

|

Oxidation catalytic converter (built-in diesel particulate filter)

|

|

6

|

Seal ring (joint pipe side)

(See Seal Ring Removal Note.)

|

|

7

|

A/F sensor

|

|

8

|

Exhaust gas temperature sensor

|

|

9

|

Joint pipe

|

|

10

|

Seal ring (front pipe side)

(See Seal Ring Removal Note.)

|

|

11

|

Turbocharger insulator No.1

|

|

12

|

Front pipe bracket No.1

|

|

13

|

Front pipe bracket No.2

|

|

14

|

Front pipe

|

|

15

|

Oil pipe (supply)

|

|

16

|

Water pipe

(See Water Pipe Removal Note)

|

|

17

|

Oil pipe (return)

|

|

18

|

Turbocharger bracket

|

|

19

|

Turbocharger insulator No.2

|

|

20

|

Exhaust manifold insulator

|

|

21

|

Turbocharger

|

|

22

|

Exhaust manifold

|

|

23

|

Tailpipe garnish

|

Exhaust System Insulator Removal/installation Note

1. Remove the exhaust system insulator in the order shown in the figure.

2. Install in the reverse order of removal.

am6zzw00004293

|

|

1

|

Insulator (front)

|

|

2

|

Insulator (middle)

|

|

3

|

Insulator (rear)

|

Seal Ring Removal Note

1. Remove the seal ring using a flathead screwdriver being careful not to damage the pipe.

am6zzw00000228

|

Water Pipe Removal Note

1. Drain the engine coolant before removing the water pipe. (See ENGINE COOLANT REPLACEMENT [MZR-CD (RF Turbo)].)

Turbocharger Removal Note

1. Remove the battery. (See BATTERY REMOVAL/INSTALLATION [MZR-CD (RF Turbo)].)

Exhaust Manifold Removal Note

1. Remove the EGR cooler before removing the exhaust manifold. (See EGR COOLER REMOVAL/INSTALLATION [MZR-CD (RF Turbo)].)

Tailpipe Garnish Replacement Note

1. Remove the spot welding on the damaged tailpipe garnish.

2. Install a new tailpipe garnish as shown in the figure.

am6zzw00012057

|

Exhaust Manifold Installation Note

1. Tighten the exhaust manifold installation nuts in the order shown.

am6zzw00003442

|

2. Install the EGR cooler. (See EGR COOLER REMOVAL/INSTALLATION [MZR-CD (RF Turbo)].)

Water Pipe Installation Note

1. Tighten the water pipe installation nuts in the order shown.

am6zzw00003443

|

2. Refill the engine coolant after Installing the water pipe. (See ENGINE COOLANT REPLACEMENT [MZR-CD (RF Turbo)].)

Oil Pipe (Supply) Installation Note

1. Tighten the oil pipe (supply) installation bolts in the order shown.

am6zzw00003444

|

Flange Surface Installation Note

1. Sand the surface shown in the figure using sandpaper and remove sanding residue, accumulated matter, and friction marks.

2. Degrease the sanded surface.

am6zzw00011899

|

Front Pipe Installation Note

1. Tighten the bolts A.

am6zzw00003445

|

2. Tighten the bolt B and nuts E.

3. Verify that brackets X, Y and Z are each properly installed.

4. Tighten the bolts C.

5. Tighten the bolts D.

Seal Ring Installation Note (Front Pipe Side)

1. Temporarily install the seal ring to the pipe so that the seal ring is even with the flange.

am6zzw00012058

|

2. Install the SST to the seal ring so that the SST is even with the flange.

am6zzw00003447

|

3. Press in the seal ring by tapping the SST using a plastic hammer until the seal ring contacts the flange.

am6zzw00003448

|

Seal Ring Installation Note (Joint Pipe Side)

1. Temporarily install the seal ring to the pipe so that the seal ring is even with the flange.

am6zzw00012058

|

2. Install the SST to the seal ring so that the SST is even with the flange.

am6zzw00003450

|

3. Press in the seal ring by tapping the SST using a plastic hammer until the seal ring contacts the flange.

am6zzw00003451

|