1. Disconnect the negative battery cable.

2. Remove the under cover.

3. Remove the splash shield.

4. Drain the engine coolant. (See ENGINE COOLANT REPLACEMENT [L3].)

5. Drain the ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [GF4AX-EL].)

6. Remove the following parts.

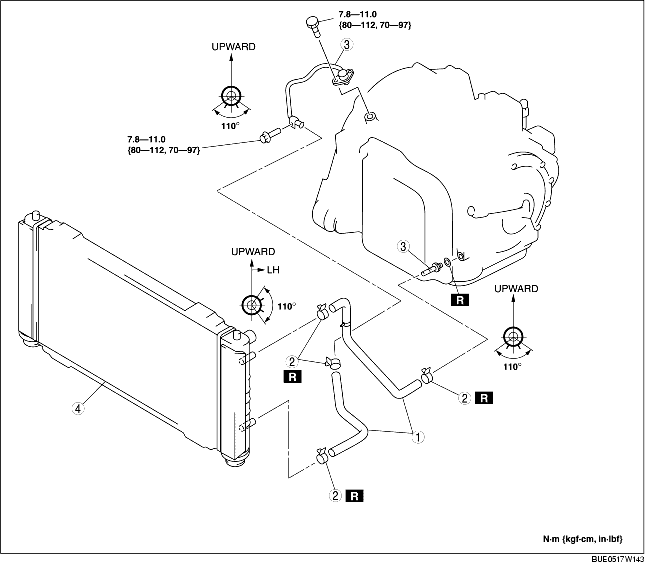

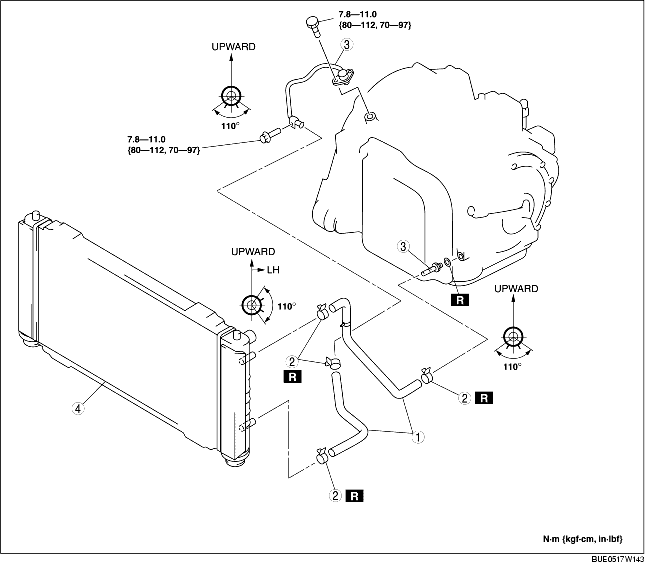

7. Remove in the order indicated in the table.

8. Install in the reverse order of removal.

9. Add ATF to the specified level. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [GF4AX-EL].)

10. Add engine coolant to the specified level. (See ENGINE COOLANT REPLACEMENT [L3].)

11. Connect the negative battery cable.

12. Inspect for oil leakage from the oil pipes and oil hoses.

13. Inspect for engine coolant leakage from the hoses.

14. Inspect the ATF level and condition. (See AUTOMATIC TRANSAXLE FLUID (ATF) INSPECTION [GF4AX-EL].)

1. The automatic transaxle oil cooler flushing must be performed whenever a transaxle is removed for service because the existing fluid may be contaminated, and to prevent contamination of new fluid.

2. Follow the instructions in the manufacturer's publication for flushing operation.

1. Apply compressed air to cooler-side opening, and blow any remaining grime and foreign material from the cooler pipes. Compressed air should be applied for no less than 1 min.

2. Align the marks, and slide the oil hose onto the oil pipe until it is fully seated as shown.

3. Install the hose clamp onto the hose. If reusing the hose, install the new hose clamp exactly on the mark left by the previous hose clamp.

4. Verify that the hose clamp does not interfere with any other components.