Body Structure

Lightweight and Highly Rigid BodyDescription

The body of the new CELICA has been made lightweight and highly rigid through the refinement of the shape and construction of each part, optimized allocation of reinforcements and members, and use of high strength sheet steel.

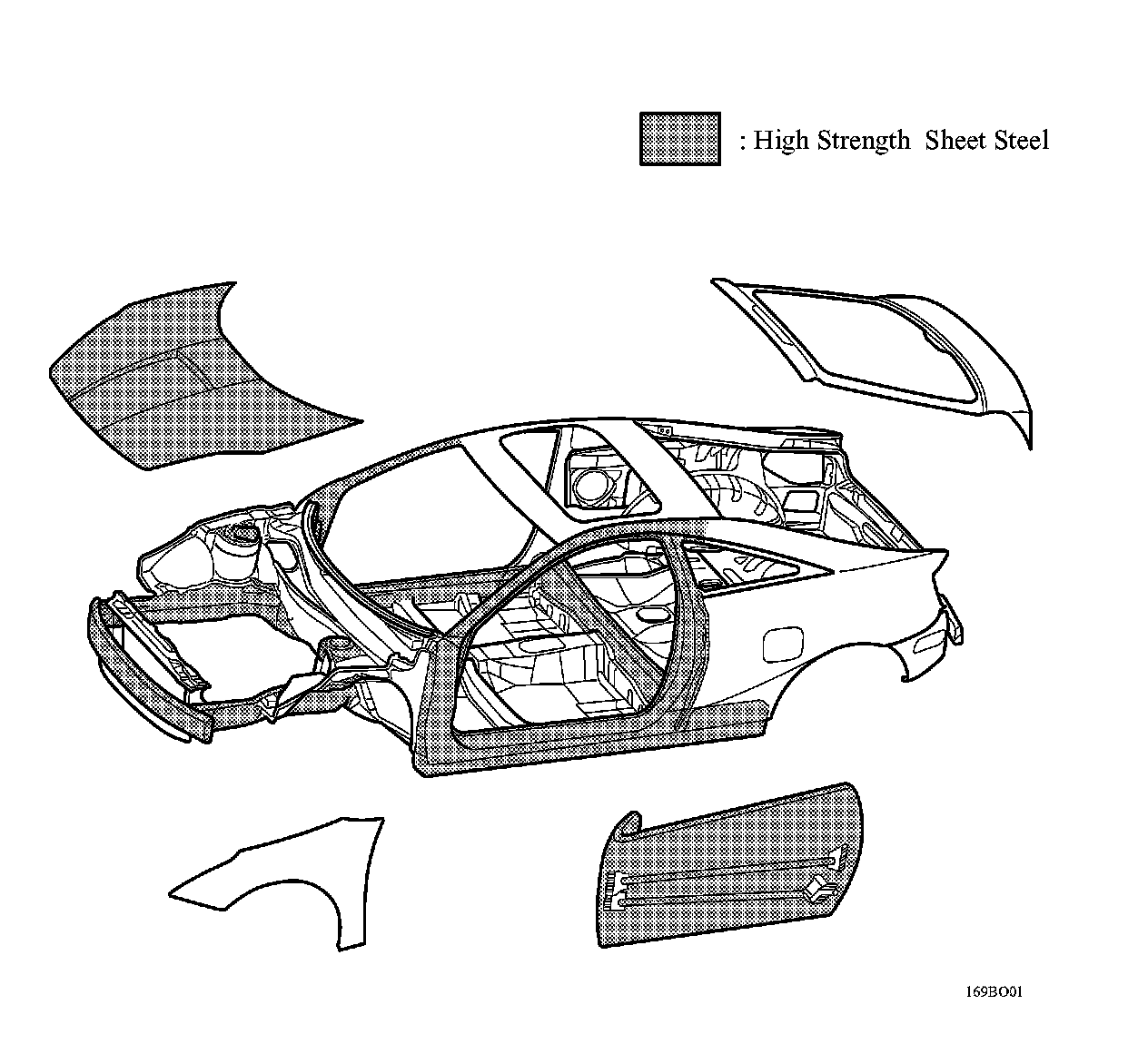

Highly Strength Sheet Steel

High strength sheet steel is used for the hood, door panels and members.

We tried to lighten the weight by increasing the use of high strength sheet steel sections.

Body Shell

The member, brace and reinforcement have been effectively located to ensure high rigidity and to realize excellent stability and controllability.

1: The areas in which the front and rear bumper reinforcements are joined to the side members have been strengthened to ensure the torsional rigidity of the entire body, as well as its lateral bending rigidity.

2: Cowl-top side braces have been adopted to ensure the body rigidity and to realize excellent stability and controllability.

3: Through the optimal construction and allocation of the front floor crossmember, seat brackets, right and left rocker panels, center floor crossmember, and the rear crossmember, a high level of body rigidity and quiet performance have been realized.

4: Reinforcements have been provided for the opening for the back door to ensure the rigidity of the back door opening.