|

ENGINE REMOVAL/INSTALLATION [L3 Turbo]

id0110b3800400

1. Remove the battery and battery tray. (See BATTERY REMOVAL/INSTALLATION [L3 Turbo].)

2. Remove the charge air cooler duct. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [L3 Turbo].)

3. Remove the air cleaner and fresh air duct component. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [L3 Turbo].)

4. Remove the front wheel and tire.

5. Remove the under cover, splash shield and mudguard.

6. Drain the engine coolant (SeeENGINE COOLANT REPLACEMENT [L3 Turbo].)

7. Drain the automatic transaxle fluid (ATF) (ATX). (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [AW6A-EL, AW6AX-EL].)

8. Remove the drive belt. (See DRIVE BELT REMOVAL/INSTALLATION [L3 Turbo].)

9. Disconnect the heater hose. (See A/C UNIT REMOVAL/INSTALLATION [FULL-AUTO AIR CONDITIONER].)

10. Disconnect the radiator hose. (See RADIATOR REMOVAL/INSTALLATION [L3 Turbo].)

11. Disconnect the brake vacuum hose. (SeeVACUUM HOSE REMOVAL/INSTALLATION.)

12. Disconnect the fuel hose and vacuum hose. (See QUICK RELEASE CONNECTOR REMOVAL/INSTALLATION [L3 Turbo].)

13. Disconnect the selector cable from the transaxle side (ATX). (See SELECTOR LEVER COMPONENT REMOVAL/INSTALLATION.)

14. Disconnect the shift cable from the transaxle side (MTX). (See SHIFT MECHANISM REMOVAL/INSTALLATION [A26MX-R].)

15. Set the clutch release cylinder out of the way (MTX). (See CLUTCH RELEASE CYLINDER REMOVAL/INSTALLATION.)

16. Disconnect the wiring harnesses. (See PCM REMOVAL/INSTALLATION [L3 Turbo].)

17. Remove the propeller shaft (4WD). (See PROPELLER SHAFT REMOVAL/INSTALLATION.)

18. Remove the front pipe and HO2S. (See EXHAUST SYSTEM REMOVAL/INSTALLATION [L3 Turbo].)

19. Disconnect the front drive shaft (RH) from the joint shaft side. (See FRONT DRIVE SHAFT REMOVAL/INSTALLATION.)

20. Disconnect the front drive shaft (LH) from the transaxle side. (See FRONT DRIVE SHAFT REMOVAL/INSTALLATION.)

21. Remove the A/C compressor with the pipes still connected. (See A/C COMPRESSOR REMOVAL/INSTALLATION [FULL-AUTO AIR CONDITIONER].) (See A/C COMPRESSOR REMOVAL/INSTALLATION [MANUAL AIR CONDITIONER].)

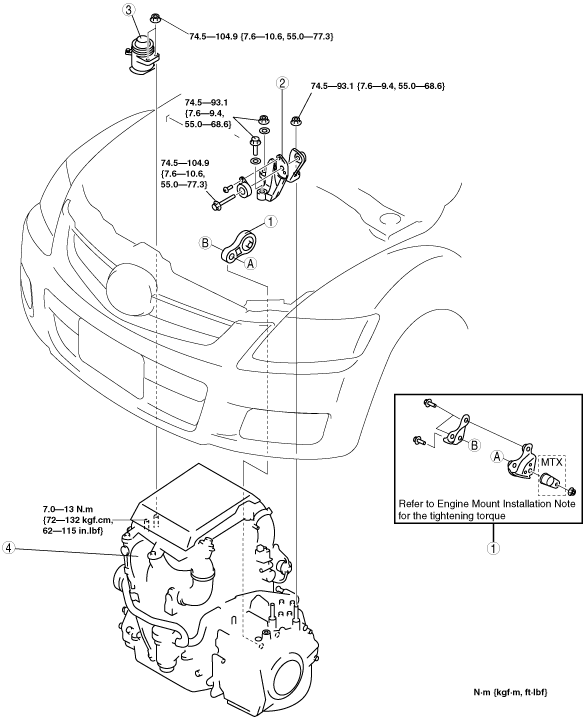

22. Remove in the order indicated in the figure.

23. Install in the reverse order of removal.

24. Start the engine, and inspect and adjust the following:

25. Perform a road test and verify that there is no abnormal vibration or noise.

acxaaw00001617

|

|

1

|

No.1 engine mount

|

|

2

|

No.4 engine mount bracket

|

|

3

|

No.3 engine mount rubber

|

|

4

|

Engine and transaxle

|

No.1 Engine Mount Removal Note

1. Remove the No.1 engine mount bracket from the underside of the vehicle.

acxaaw00001532

|

2. Remove the No.1 engine mount rubber and the front crossmember as a single unit. (See FRONT CROSSMEMBER REMOVAL/INSTALLATION [L.H.D.].) (See FRONT CROSSMEMBER REMOVAL/INSTALLATION [R.H.D.].)

acxuuw00000187

|

No.3 Engine Mount Rubber, No.4 Engine Mount Bracket Removal Note

1. Secure the engine and transaxle using an engine jack.

acxaaw00001523

|

Engine Mount Installation Note

1. Tighten the No. 3 engine mount bracket stud bolt.

acxuuw00000189

|

2. Secure the engine and transaxle using an engine jack.

acxaaw00001523

|

3. Temporarily tighten the No.1 engine mount bracket in the order shown in the figure.

acxaaw00001584

|

4. Temporarily tighten the No.3 engine mount nuts.

5. Tighten the No.3 engine mount nuts in the order shown in the figure.

acxuuw00000191

|

6. Temporarily tighten the No.4 engine mount bracket in the order shown in the figure.

ATX

acxuuw00000192

|

MTX

acxaaw00000928

|

7. Tighten the No.4 engine mount bracket in the order shown in the figure.

ATX

acxuuw00000193

|

MTX

acxaaw00000929

|

Tightening torque

|

Installation position |

Tightening torque |

|---|---|

|

1―3

|

74.5—93.1 N·m {7.6—9.4 kgf·m, 55.0—68.6 ft·lbf}

|

|

4

|

74.5—104.9 N·m {7.6—10.6 kgf·m, 55.0—77.3 ft·lbf}

|

acxaaw00001232

|

8. Tighten the No.1 engine mount bracket bolt A and B in order of A→B.

acxaaw00001591

|

9. Tighten bolt C.

acxaaw00001620

|