Description

Brake system warning light turns on

Possible cause

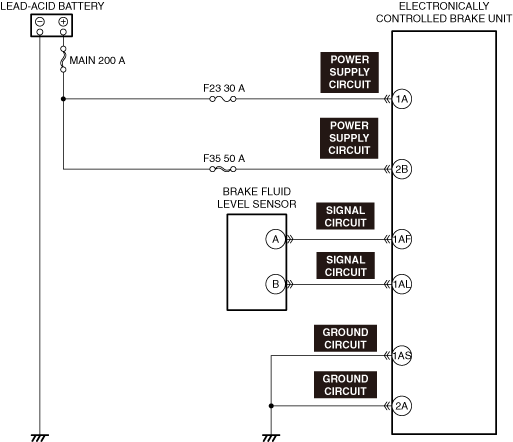

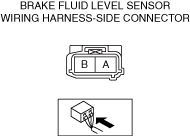

• Brake fluid level is low

• Brake fluid level sensor stuck on

• Short to ground in brake fluid level sensor signal circuit

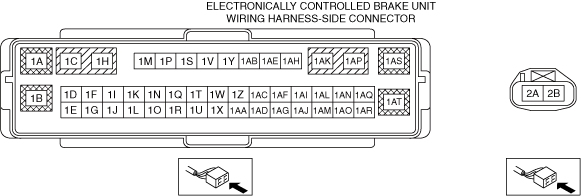

• Electronically controlled brake unit connector is disconnected (circuit that turns on ABS warning light, TCS/DSC operation indicator light, brake system warning light, and TCS OFF indicator light if electronically controlled brake unit connector is disconnected)

• Electronically controlled brake unit detects malfunction (input/output device malfunction)

• Electronically controlled brake unit detects decrease in power supply voltage

• Poor ground in electronically controlled brake unit (If electronically controlled brake unit ground is not secured properly, ABS warning light, TCS/DSC operation indicator light, brake warning light, and TCS OFF indicator light turn on, but no DTC is output)

• Electronically controlled brake unit does not activate

• Electronically controlled brake unit internal malfunction

• Instrument cluster malfunction