|

1

|

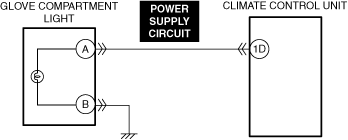

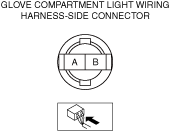

INSPECT GLOVE COMPARTMENT LIGHT CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

2

|

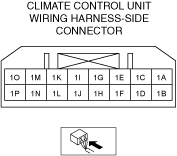

INSPECT CLIMATE CONTROL UNIT CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

3

|

INSPECT GLOVE COMPARTMENT LIGHT POWER SUPPLY CIRCUIT FOR SHORT TO POWER SUPPLY

• Inspect the applicable circuit for a short to power supply.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

4

|

INSPECT GLOVE COMPARTMENT LIGHT FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

5

|

INSPECT CLIMATE CONTROL UNIT FOR MALFUNCTION DEPENDING ON REPEATABILITY

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Perform the DTC inspection for dash-electrical supply unit.

• Is the same DTC displayed?

|

Yes

|

Refer to the CAN (controller area network) malfunction diagnosis flow to inspect for a CAN communication error.

If CAN communication is normal, replace the malfunctioning location and perform the repair completion verification.

|

|

No

|

Go to repair completion verification 2.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Perform the DTC inspection for dash-electrical supply unit.

• Is the same DTC displayed?

|

Yes

|

Refer to the CAN (controller area network) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction is not resolved, replace the dash-electrical supply unit, then go to the next step.

|

|

No

|

Go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF OTHER DTCs ARE DISPLAYED

• Perform the DTC inspection.

• Is a DTC displayed?

|

Yes

|

Repair the malfunctioning part according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|