|

a30zzw00006559

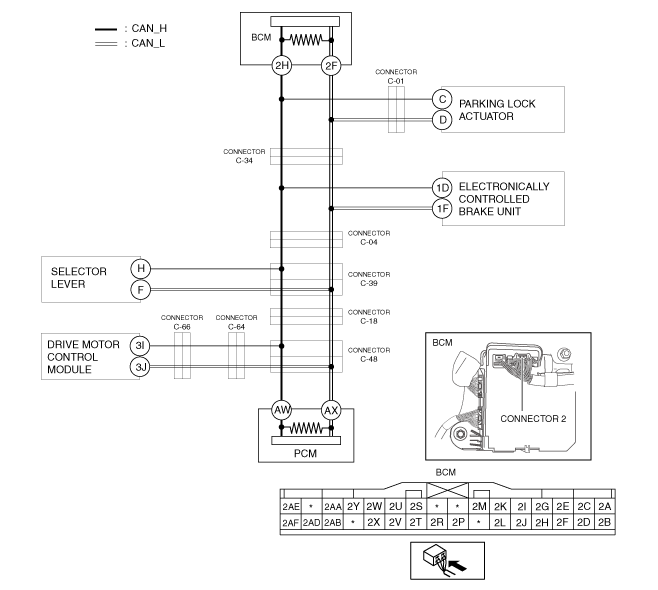

DETERMINING SHORT TO POWER SUPPLY LOCATION (CAN-BUS No.2) [R.H.D.]

id100226002300

High Voltage Part Inspection And Removal/Installation Notes

System Wiring Diagram

a30zzw00006559

|

Determination Procedure

|

Step |

Inspection |

Action |

|

|---|---|---|---|

|

1

|

INSPECT BODY CONTROL MODULE (BCM) FOR SHORT TO POWER SUPPLY

• Switch the main power OFF.

• Disconnect the negative lead-acid battery terminal.

• Disconnect the connector 2 which has body control module (BCM) terminals 2H and 2F.

• Connect the connector C-34.

• Connect the negative lead-acid battery terminal.

• Switch the main power ON (READY off).

• Measure the voltage at body control module (BCM) terminals 2H and 2F (wiring harness side).

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Replace the body control module (BCM) because there is a short to the power supply in the body control module (BCM).

|

|

No

|

Go to the next step.

|

||

|

2

|

INSPECT CAN LINE BETWEEN BODY CONTROL MODULE (BCM) AND CONNECTOR C-34 FOR SHORT TO POWER SUPPLY

• Switch the main power OFF.

• Disconnect the negative lead-acid battery terminal.

• Disconnect the connector C-34.

• Connect the negative lead-acid battery terminal.

• Switch the main power ON (READY off).

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Go to Step 5.

|

|

No

|

Go to the next step.

|

||

|

3

|

INSPECT CAN LINE BETWEEN PARKING LOCK ACTUATOR AND CONNECTOR C-01

• Switch the main power OFF.

• Disconnect the negative lead-acid battery terminal.

• Disconnect the connector C-01.

• Connect the negative lead-acid battery terminal.

• Switch the main power ON (READY off).

• Measure the voltage at body control module (BCM) terminals 2H and 2F.

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness between the body control module (BCM), connector C-34 and connector C-01 because the wiring harness is shorted to the power supply.

|

||

|

4

|

INSPECT PARKING LOCK ACTUATOR FOR SHORT TO POWER SUPPLY

• Switch the main power OFF.

• Disconnect the negative lead-acid battery terminal.

• Disconnect the parking lock actuator connector.

• Connect the connector C-01.

• Connect the negative lead-acid battery terminal.

• Switch the main power ON (READY off).

• Measure the voltage at body control module (BCM) terminals 2H and 2F.

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Replace the parking lock actuator because there is a short to the power supply in the parking lock actuator.

|

|

No

|

Repair or replace the wiring harness between the parking lock actuator and connector C-01 because the wiring harness is shorted to the power supply.

|

||

|

5

|

INSPECT CAN LINE BETWEEN CONNECTOR C-34 AND CONNECTOR C-04 FOR SHORT TO POWER SUPPLY

• Switch the main power OFF.

• Disconnect the negative lead-acid battery terminal.

• Disconnect the connector C-04.

• Connect the connector C-34.

• Connect the negative lead-acid battery terminal.

• Switch the main power ON (READY off).

• Measure the voltage at body control module (BCM) terminals 2H and 2F.

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Go to Step 7.

|

|

No

|

Go to the next step.

|

||

|

6

|

INSPECT ELECTRONICALLY CONTROLLED BRAKE UNIT FOR SHORT TO POWER SUPPLY

• Switch the main power OFF.

• Disconnect the negative lead-acid battery terminal.

• Disconnect the electronically controlled brake unit connector.

• Connect the connector C-04.

• Connect the negative lead-acid battery terminal.

• Switch the main power ON (READY off).

• Measure the voltage at body control module (BCM) terminals 2H and 2F.

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Replace the electronically controlled brake unit because there is a short to the power supply in the electronically controlled brake unit.

|

|

No

|

Repair or replace the wiring harness between the electronically controlled brake unit and connector C-04 and connector C-34 because the wiring harness is shorted to the power supply.

|

||

|

7

|

INSPECT CAN LINE BETWEEN CONNECTOR C-34 AND CONNECTOR C-04 FOR SHORT TO POWER SUPPLY

• Switch the main power OFF.

• Disconnect the negative lead-acid battery terminal.

• Disconnect the connector C-04.

• Connect the connector C-34.

• Connect the negative lead-acid battery terminal.

• Switch the main power ON (READY off).

• Measure the voltage at body control module (BCM) terminals 2H and 2F.

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness between the connector C-04 and connector C-34 because the wiring harness is shorted to the power supply.

|

||

|

8

|

INSPECT CAN LINE BETWEEN CONNECTOR C-04 AND CONNECTOR C-39 FOR SHORT TO POWER SUPPLY

• Switch the main power OFF.

• Disconnect the negative lead-acid battery terminal.

• Disconnect the connector C-39.

• Connect the connector C-04.

• Connect the negative lead-acid battery terminal.

• Switch the main power ON (READY off).

• Measure the voltage at body control module (BCM) terminals 2H and 2F.

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness between the connector C-04 and connector C-39 because the wiring harness is shorted to the power supply.

|

||

|

9

|

INSPECT CAN LINE BETWEEN SELECTOR LEVER AND CONNECTOR C-39 FOR SHORT TO POWER SUPPLY

• Measure the voltage at selector lever terminals H and F.

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Go to Step 11.

|

|

No

|

Go to the next step.

|

||

|

10

|

INSPECT SELECTOR LEVER FOR SHORT TO POWER SUPPLY

• Switch the main power OFF.

• Disconnect the negative lead-acid battery terminal.

• Disconnect the selector lever connector.

• Connect the connector C-39.

• Connect the negative lead-acid battery terminal.

• Switch the main power ON (READY off).

• Measure the voltage at body control module (BCM) terminals 2H and 2F.

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Replace the selector lever because there is a short to the power supply in the selector lever.

|

|

No

|

Repair or replace the wiring harness between the selector lever and connector C-39 because the wiring harness is shorted to the power supply.

|

||

|

11

|

INSPECT CAN LINE BETWEEN CONNECTOR C-39 AND CONNECTOR C-18 FOR SHORT TO POWER SUPPLY

• Switch the main power OFF.

• Disconnect the negative lead-acid battery terminal.

• Disconnect the connector C-18.

• Connect the connector C-39.

• Connect the negative lead-acid battery terminal.

• Switch the main power ON (READY off).

• Measure the voltage at body control module (BCM) terminals 2H and 2F.

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness between the connector C-39 and connector C-18 because the wiring harness is shorted to the power supply.

|

||

|

12

|

INSPECT CAN LINE BETWEEN CONNECTOR C-18 AND CONNECTOR C-48 FOR SHORT TO POWER SUPPLY

• Switch the main power OFF.

• Disconnect the negative lead-acid battery terminal.

• Disconnect the connector C-48.

• Connect the connector C-18.

• Connect the negative lead-acid battery terminal.

• Switch the main power ON (READY off).

• Measure the voltage at body control module (BCM) terminals 2H and 2F.

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness between the connector C-48 and connector C-18 because the wiring harness is shorted to the power supply.

|

||

|

13

|

INSPECT CAN LINE BETWEEN PCM AND CONNECTOR C-48 FOR SHORT TO POWER SUPPLY

• Measure the voltage at PCM terminals AW and AX.

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 17.

|

||

|

14

|

INSPECT CAN LINE BETWEEN CONNECTOR C-48 AND CONNECTOR C-64 FOR SHORT TO POWER SUPPLY

• Switch the main power OFF.

• Disconnect the negative lead-acid battery terminal.

• Disconnect the connector C-64.

• Connect the connector C-48.

• Connect the negative lead-acid battery terminal.

• Switch the main power ON (READY off).

• Measure the voltage at body control module (BCM) terminals 2H and 2F.

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness between the connector C-64 and connector C-48 because the wiring harness is shorted to the power supply.

|

||

|

15

|

INSPECT CAN LINE BETWEEN CONNECTOR C-64 AND CONNECTOR C-66 FOR SHORT TO POWER SUPPLY

• Switch the main power OFF.

• Disconnect the negative lead-acid battery terminal.

• Disconnect the connector C-64.

• Connect the connector C-66.

• Connect the negative lead-acid battery terminal.

• Switch the main power ON (READY off).

• Measure the voltage at body control module (BCM) terminals 2H and 2F.

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness between the connector C-64 and connector C-66 because the wiring harness is shorted to the power supply.

|

||

|

16

|

INSPECT DRIVE MOTOR CONTROL MODULE FOR SHORT TO POWER SUPPLY

• Switch the main power OFF.

• Disconnect the negative lead-acid battery terminal.

• Disconnect the drive motor control module connector.

• Connect the connector C-66.

• Connect the negative lead-acid battery terminal.

• Switch the main power ON (READY off).

• Measure the voltage at body control module (BCM) terminals 2H and 2F.

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Replace the drive motor control module connector because there is a short to the power supply in the drive motor control module connector.

|

|

No

|

Repair or replace the wiring harness between the drive motor control module and connector C-66 because the wiring harness is shorted to the power supply.

|

||

|

17

|

INSPECT PCM FOR SHORT TO POWER SUPPLY

• Switch the main power OFF.

• Disconnect the negative lead-acid battery terminal.

• Disconnect the PCM connector.

• Connect the connector C-48.

• Connect the negative lead-acid battery terminal.

• Switch the main power ON (READY off).

• Measure the voltage at body control module (BCM) terminals 2H and 2F.

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Replace the PCM because there is a short to the power supply in the PCM.

(See PCM REMOVAL/INSTALLATION.)

|

|

No

|

Repair or replace the wiring harness between the PCM and connector C-48 because the wiring harness is shorted to the power supply.

|

||