|

1

|

RECORD VEHICLE STATUS WHEN DTC WAS DETECTED TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the snapshot data.

-

Note

-

• Recording can be facilitated using the screen capture function of the PC.

|

—

|

Go to the next step.

|

|

2

|

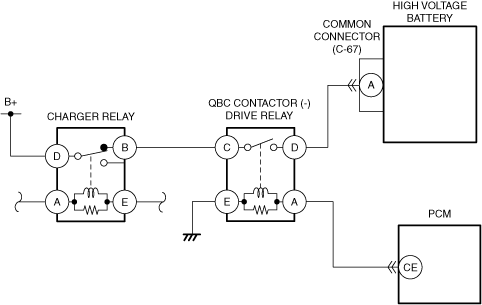

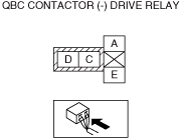

INSPECT QBC CONTACTOR (-) DRIVE RELAY FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

4

|

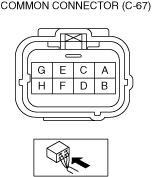

INSPECT COMMON CONNECTOR (C-67) CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Common connector (C-67) connector (high voltage battery side) malfunction:

• Replace the high voltage battery, then go to the repair completion verification 1.

Common connector (C-67) connector (vehicle wiring harness side) malfunction:

• Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

5

|

INSPECT QBC CONTACTOR (-) DRIVE RELAY CONTROL CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

6

|

INSPECT QBC CONTACTOR (-) DRIVE RELAY CONTROL CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for a open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

7

|

INSPECT WIRING HARNESS BETWEEN QBC CONTACTOR (-) DRIVE RELAY AND COMMON CONNECTOR (C-67) CONNECTOR FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

8

|

INSPECT WIRING HARNESS BETWEEN QBC CONTACTOR (-) DRIVE RELAY AND COMMON CONNECTOR (C-67) CONNECTOR FOR OPEN CITCUIT

• Inspect the applicable circuit for a open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

9

|

VERIFY WHETHER MALFUNCTION IS PRESENT OR PAST

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Replicate the vehicle conditions at the time the DTC was detected using the following procedure.

-

Warning

-

• While performing this step, always operate the vehicle in a safe and lawful manner.

• When the M-MDS is used to observe monitor system status while driving, be sure to have another technician with you, or record the data in the M-MDS using the PID/DATA MONITOR AND RECORD capturing function and inspect later.

-

― Drive the vehicle under the snapshot data condition.

• Perform the DTC inspection for the PCM.

• Is DTC P0D0E:00 a present malfunction?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the high voltage battery, then go to the repair completion verification1.

|

|

No

|

Go to the repair completion verification 2.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Replicate the vehicle conditions at the time the DTC was detected using the following procedure.

-

Warning

-

• While performing this step, always operate the vehicle in a safe and lawful manner.

• When the M-MDS is used to observe monitor system status while driving, be sure to have another technician with you, or record the data in the M-MDS using the PID/DATA MONITOR AND RECORD capturing function and inspect later.

-

― Drive the vehicle under the snapshot data condition.

• Perform the DTC inspection for the PCM.

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the PCM, then go to the next step.

|

|

No

|

Go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF OTHER DTCs DISPLAYED

• Perform the DTC inspection.

• Are any other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|