|

1

|

VERIFY PCM DTC

• Using the M-MDS, perform the PCM DTC inspection.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

DTC troubleshooting completed, then go to the next step.

|

|

No

|

Go to the next step.

|

|

2

|

INSPECT BATTERY

• Is there any malfunction?

|

Yes

|

Charge or replace the battery, then go to Step7.

|

|

No

|

Go to the next step.

|

|

3

|

VERIFY DC-DC CONVERTER DTC

• Using the M-MDS, perform the DC-DC converter DTC inspection.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

DTC troubleshooting completed, then go to the next step.

|

|

No

|

Go to the next step.

|

|

4

|

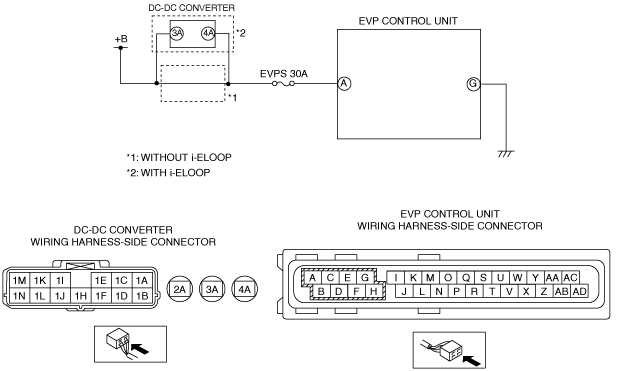

INSPECT FUSE CONDITION

• Is the fuse (EVPS 30A) normal?

|

Yes

|

Go to the next step.

|

|

No

|

• If the fuse is blown:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between fuse and EVP control unit terminal A.

If there is a common connector:

-

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which has a short to ground.

• Replace the fuse.

• If the fuse is damaged:

-

― Replace the fuse.

Go to Step7.

|

|

5

|

INSPECT EVP CONTROL UNIT POWER CIRCUIT FOR OPEN CIRCUIT

• Switch the ignition OFF.

• Disconnect the EVP control unit connector.

• Switch the ignition ON (engine off).

• Measure the voltage between EVP control unit terminal A (wiring harness-side)—body ground.

• Is the voltage 10 V or more?

|

Yes

|

Go to the next Step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector in the followings.

• Battery—DC-DC converter terminal 3A

• DC-DC converter terminal 4A—EVP control unit terminal A

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Go to Step7.

|

|

6

|

INSPECT EVP CONTROL UNIT GROUND CIRCUIT FOR OPEN CIRCUIT OR POOR GROUND

• Switch the ignition OFF.

• Disconnect the EVP control unit connector.

• Measure the resistance between EVP control unit terminal G (wiring harness-side) and body ground.

• Is the resistance 0—1 ohm?

|

Yes

|

Go to the next step.

|

|

No

|

• If the open circuit could be detected in the wiring harness:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between EVP control unit terminal G and body ground.

If there is a common connector:

-

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which has an open circuit.

― Go to the next step.

• If the resistance is out of specification:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between EVP control unit terminal G and body ground.

If there is a common connector:

-

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a poor ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which has a poor ground.

― Go to the next step.

|

|

7

|

VERIFY DTC TROUBLESHOOTING COMPLETED

• Using the M-MDS, clear the DTC from the EVP control unit.

• Using the M-MDS, perform the EVP control unit DTC inspection.

• Is the same DTC present?

|

Yes

|

Repeat the inspection from Step1.

If the malfunction recurs, replace the EVP control unit, then go to the next step.

|

|

No

|

Go to the next step.

|

|

8

|

VERIFY NO DTC IS PRESENT

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

DTC troubleshooting completed.

|