|

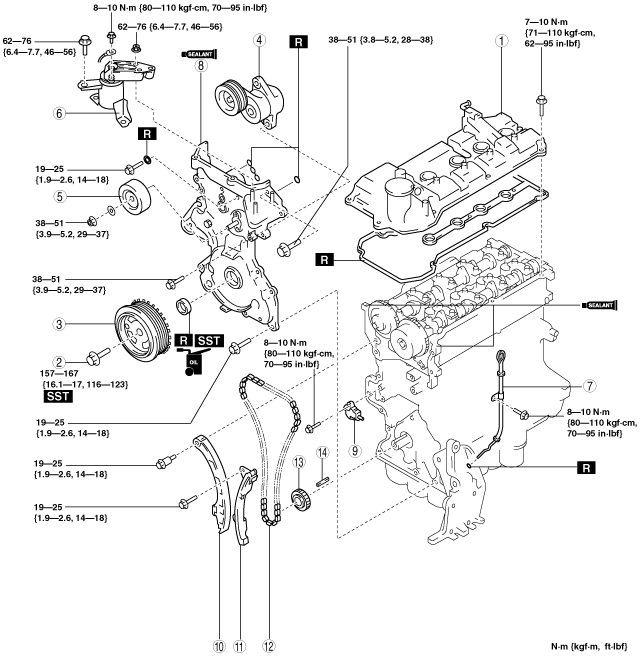

TIMING CHAIN REMOVAL/INSTALLATION [ZJ, ZY]

id0110b7801000

1. Disconnect the negative battery cable.

2. Drain the engine coolant. (See ENGINE COOLANT REPLACEMENT [ZJ, ZY].)

3. Perform the following procedure.

4. Remove the ignition coils. (See IGNITION COIL REMOVAL/INSTALLATION [ZJ, ZY].)

5. Disconnect the ventilation hose. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [ZJ, ZY].)

6. Set the vacuum hose out of the way. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [ZJ, ZY].)

7. Set the cooler pipe and the cooler hose out of the way. (With A/C) (See REFRIGERANT LINE REMOVAL/INSTALLATION.)

8. Remove the OCV. (See OIL CONTROL VALVE (OCV) REMOVAL/INSTALLATION [ZJ, ZY].)

9. Remove the drive belt. (See DRIVE BELT REMOVAL/INSTALLATION [ZJ, ZY].)

10. Remove the crankshaft position (CKP) sensor. (See CRANKSHAFT POSITION (CKP) SENSOR REMOVAL/INSTALLATION [ZJ, ZY].)

11. Remove the generator. (See GENERATOR REMOVAL/INSTALLATION [ZJ, ZY].)

12. Remove the water pump. (See WATER PUMP REMOVAL/INSTALLATION [ZJ, ZY].)

13. Remove in the order indicated in the table.

14. Install in the reverse order of removal.

15. Start the engine, and inspect the following and adjust them if necessary.

am2zzw00001754

|

|

1

|

Cylinder head cover

|

|

2

|

Crankshaft pulley lock bolt

|

|

3

|

Crankshaft pulley

|

|

4

|

Drive belt auto tensioner

|

|

5

|

Idler

|

|

6

|

No.3 engine mount

|

|

7

|

Oil level gauge pipe

|

|

8

|

Engine front cover

|

|

9

|

Chain tensioner

(See Chain Tensioner Removal Note.)

|

|

10

|

Chain tensioner arm

|

|

11

|

Chain guide

|

|

12

|

Timing chain

(See Timing Chain Removal Note.)

|

|

13

|

Crankshaft sprocket

|

|

14

|

Key

|

Crankshaft Pulley Lock Bolt Removal Note

1. Fix the crankshaft pulley using the SSTs, and remove the crankshaft pulley lock bolt.

am2zzw00001755

|

No.3 Engine Mount Removal Note

am2zzw00003727

|

1. Support the clutch housing (MTX) or the converter housing (ATX) using a jack with a wood slab of appropriate size inserted to secure the housing.

am2zzw00002595

|

Engine Front Cover Removal Note

1. Remove the front oil seal using a flathead screwdriver.

am2zzw00000108

|

Chain Tensioner Removal Note

1. Push down the link plate of the timing chain tensioner using a thin flathead screwdriver (precision screwdriver), and release the plunger lock.

am2zzw00000109

|

2. Push back the plunger slowly in the direction shown in the figure with the link plate still pushed down.

am2zzw00000110

|

3. Free the link plate with the plunger still pressed down.

4. Release the pressure slightly from the plunger, and move the plunger back and forth 2—3 mm{0.08—0.11 in}.

5. Insert an approx. 1.5 mm {0.06 in} wire or the paper clip where the link plate hole and the tensioner body hole overlap to fix the link plate and lock the plunger.

am2zzw00000111

|

Timing Chain Removal Note

1. Rotate the crankshaft clockwise and align the key groove of the crankshaft sprocket to the timing mark, and then position the No.1 cylinder to TDC.

am2zzw00000112

|

2. Align the timing marks on the camshaft sprockets so that they form a straight line in alignment with the upper horizontal surface of the cylinder head.

am2zzw00000113

|

3. Remove the timing chain.

Timing Chain Installation Note

1. Align the key groove of the crank sprocket to the timing mark, and then position the No.1 cylinder to TDC.

am2zzw00000114

|

2. Align the timing marks on the camshaft sprockets so that they form a straight line in alignment with the upper horizontal surface of the cylinder head.

am2zzw00000115

|

3. Install the timing chain.

4. After installing the chain adjuster, remove the wire or the paper clip installed to the chain tensioner, and apply tension to the timing chain. (Remove the installed stopper when installing the new chain tensioner.)

am2zzw00000116

|

5. Verify that there is no slack on the timing chain, and then verify that each sprocket is positioned in the proper place again.

6. Rotate the crankshaft clockwise twice, and then inspect the valve timing.

Engine Front Cover Installation Note

1. Apply the silicon sealant to the engine front cover as shown in the figure.

am2zzw00001758

|

2. Tighten the engine front cover installation bolts in the order shown in the figure.

am2zzw00001759

|

|

Bolt number |

Tightening torque |

|---|---|

|

1—6, 8, 10,

12—15, 17, 18

|

19—25 N·m {1.9—2.6 kgf·m, 14—18 ft·lbf}

|

|

7, 11, 16

|

38—51 N·m {3.8—5.2 kgf·m, 28—38 ft·lbf}

|

|

9

|

8—10 N·m {80—110 kgf·cm, 70—95 in·lbf}

|

3. Apply clean engine oil to the new front oil seal.

4. Insert the front oil seal into the engine front cover by hand.

5. Tap in the front oil seal using the SST and a hammer.

am2zzw00001760

|

am2zzw00002269

|

No.3 Engine Mount Installation Note

1. Install the No.3 engine mount, and then temporarily tighten the installation bolts and nuts.

2. Tighten the installation bolts and nuts by order of A,B.

am2zzw00001762

|

Crankshaft Pulley Lock Bolt Installation Note

1. Fix the crankshaft pulley using the SSTs.

am2zzw00001755

|

2. Tighten the crankshaft pulley lock bolt.

Cylinder Head Cover Installation Note

1. Apply silicon sealant as shown in the figure.

am2zzw00000122

|

2. Tighten the cylinder head cover installation bolts in the order shown in the figure.

am2zzw00000123

|