STEP

INSPECTION

ACTION

1

• Start the engine, and drive the vehicle.

-

― Does the speedometer needle move smoothly?― Does the speedometer needle indicate correct speed?

Yes

Troubleshooting completed. (The system is normal.)

No

Go to the next step.

2

• Reactive the DTC of PCM, ABS CM and/or DSC CM using M-MDS.

(See ON-BOARD DIAGNOSIS [ABS].)

• Is the DTC detected?

Yes

Go to applicable DTC troubleshooting procedure.

(See DTC TABLE [MZR 1.3, MZR 1.5].)

(See DTC TABLE [MZ-CD 1.6].)

(See ON-BOARD DIAGNOSIS [ABS].)

No

Go to the next step.

3

• Start the engine.

• Verify that the tachometer indication and high engine coolant temperature warning light illumination.

• Do the tachometer and high engine coolant temperature warning light work properly?

Yes

Go to the next step.

No

Go to Step 5.

4

• Monitor the following PIDs for the ABS CM or the DSC CM using the M-MDS: WSPD_LF, WSPD_LR, WSPD_RF, WSPD_RR

-

Caution

-

• To prevent an accident, work with two people when the vehicle is being driven. (One drives the vehicle and the other operates the M-MDS.)

• Drive the vehicle and compare the M-MDS monitored value with the speedometer indication.

• Does the M-MDS monitored value correspond to the speedometer indication?

Yes

Verify that the PCM, ABS HU/CM and/or DSC HU/CM connector is connected securely.

If the PCM, ABS HU/CM or DSC HU/CM connector is poor connection:

Connect the PCM, ABS HU/CM and/or DSC HU/CM connector securely.

If malfunction is in the PCM, ABS HU/CM and/or DSC HU/CM side connector:

Replace the PCM, ABS HU/CM and/or DSC HU/CM.

If malfunction is in vehicle side connector:

Repair or replace malfunctioning part.

If malfunction is not detected:

Inspect the ABS wheel-speed sensor and related part.

No

Replace the instrument cluster.

5

• Reactive the DTC of instrument cluster using M-MDS.

• Is the DTC detected?

Yes

Go to the applicable DTC troubleshooting procedure.

No

Go to the next step.

6

• Disconnect the negative battery cable.

• Measure the resistance between the DLC-2 terminals F and E.

• Is the resistance below 60 ohms?

Yes

Go to the next step.

No

Go to Step 8.

7

• Disconnect the negative battery cable.

• Inspect the DLC-2 terminals F and E for short to power supply or ground.

• Is there any malfunction?

Yes

Inspect the wiring harness and CAN system-related module.

Repair or replace the malfunctioning part.

No

Replace the instrument cluster.

8

• Turn the ignition switch off.

• Inspect the instrument cluster connector terminals for poor connection (such as damaged/pulled-out pins, and corrosion).

• Are the terminals normal?

Yes

Go to the next step.

No

Repair or replace the terminal.

9

• Disconnect the negative battery cable.

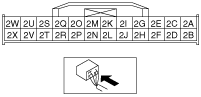

• Measure the resistance between the instrument cluster connector terminals 2B and 2D.

• Is the resistance 114—126 ohms?

Yes

Inspect the wiring harness and CAN system-related module.

Repair or replace the malfunctioning part.

No

Replace the instrument cluster.