DTC P2797:00

Electric AT Oil Pump

DETECTION CONDITION

• The turbine speed exceeds a certain value several times when returning from i-stop (engine stop control).

Diagnostic support note

• The MIL does not illuminate.

• The AT warning light does not illuminate.

• PENDING CODE is not available.

• FREEZE FRAME DATA is not available.

• The DTC is stored in the TCM memory.

POSSIBLE CAUSE

• ATF deterioration

• Insufficient ATF level

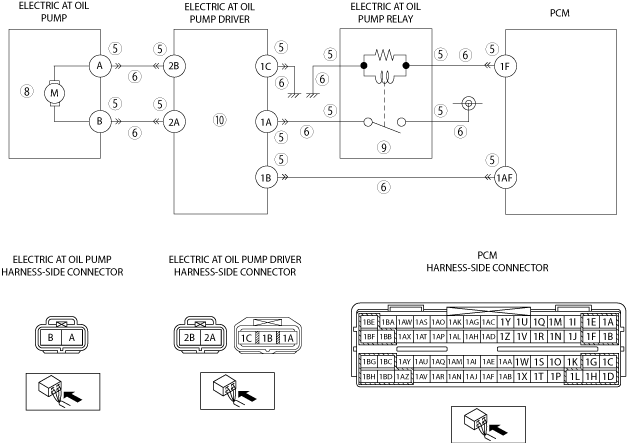

• Open circuit, or short to ground in wiring harness between PCM terminal 1F and electric AT oil pump relay

• Open circuit in wiring harness between electric AT oil pump relay and body ground

• Open circuit, or short to ground in wiring harness between battery and electric AT oil pump relay

• Open circuit, or short to ground in wiring harness between electric AT oil pump relay and electric AT oil pump driver terminal 1A

• Open circuit, or short to ground in wiring harness between PCM terminal 1AF and electric AT oil pump driver terminal 1B

• Open circuit in wiring harness between electric AT oil pump driver terminal 1C and body ground

• Open circuit, or short to ground in wiring harness between electric AT oil pump terminal A and electric AT oil pump driver terminal 2B

• Open circuit, or short to ground in wiring harness between electric AT oil pump terminal B and electric AT oil pump driver terminal 2A

• Connector and terminal malfunctions

• Line pressure is low

• Electric AT oil pump malfunction

• Electric AT oil pump relay malfunction

• Electric AT oil pump driver malfunction

• Primary control valve body malfunction

• TCM malfunction

• PCM malfunction