CRANKSHAFT POSITION (CKP) SENSOR INSPECTION [MZR 2.0, MZR 2.5]

id0140e4800500

Visual Inspection

-

Caution

-

• When foreign material such as an iron chip is on the CKP sensor, it can cause abnormal output from the sensor because of flux turbulence and adversely affect the engine control. Be sure there is no foreign material on the CKP sensor when replacing.

• Do not assemble the CKP sensor or change the installation position using any method other than the following. Otherwise, it could negatively affect engine controls, such as the ignition timing and fuel injection.

1. Remove the battery cover. (See BATTERY REMOVAL/INSTALLATION [MZR 2.0, MZR 2.5].)

2. Disconnect the negative battery cable. (See BATTERY REMOVAL/INSTALLATION [MZR 2.0, MZR 2.5].)

3. Remove the aerodynamic under cover No.2 and splash shield as a single unit. (See AERODYNAMIC UNDER COVER NO.2 REMOVAL/INSTALLATION.) (See SPLASH SHIELD REMOVAL/INSTALLATION.)

4. Disconnect the CKP sensor connector.

5. Remove the CKP sensor. (See CRANKSHAFT POSITION (CKP) SENSOR REMOVAL/INSTALLATION [MZR 2.0, MZR 2.5].)

6. Verify that there are no metal shavings on the sensor.

-

• If there is a malfunction, remove any metal shavings that are adhering.

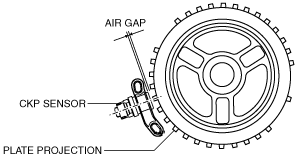

Air Gap Inspection

1. Verify that the CKP sensor is securely installed. (See CRANKSHAFT POSITION (CKP) SENSOR REMOVAL/INSTALLATION [MZR 2.0, MZR 2.5].)

2. Using a thickness gauge, measure the air gap between the plate projections at the back of crankshaft pulley and the CKP sensor.

-

• If not within the specification, inspect the plate projections for cracks or bending.

-

-

CKP sensor air gap

-

0.5—1.5 mm {0.02—0.05 in}

Voltage Inspection

-

Caution

-

• When foreign material such as an iron chip is on the CKP sensor, it can cause abnormal output from the sensor because of flux turbulence and adversely affect the engine control. Be sure there is no foreign material on the CKP sensor when replacing.

• Do not assemble the CKP sensor or change the installation position using any method other than the following. Otherwise, it could negatively affect engine controls, such as the ignition timing and fuel injection.

• If the wiring harnesses or waterproof connectors are damaged, water penetrating the connector will cause a sensor malfunction. To prevent this, be careful not to damage wiring harnesses or waterproof connectors.

1. Idle the engine.

2. Measure the CKP sensor output wave pattern using an oscilloscope. (See PCM INSPECTION [MZR 2.0, MZR 2.5].)

-