1. Engine control system check

Refer to "51.Engine Control 1A.Troubleshooting(4JJ3 with DPD) Diagnostic system check-engine controls".

2. Instrument panel cluster display illumination check

1) Turn ON the ignition switch for 30 seconds, and check the DPD operator regeneration indicator light in the instrument panel cluster. Does the DPD operator regeneration indicator light illuminate and then turn OFF?

Yes

=>Go to DPD components inspection.

No

=>Go to Instrument panel cluster setting verification.

3. Instrument panel cluster setting verification

1) Display the Module Information parameter with a scan tool.

2) Verify that the DPD Indicator Light setting is Available. Is the DPD Indicator Light setting Available?

Refer to "9.Body, Cab, Accessories 9E.Instrumentation, Driver Info. instrument panel cluster setting".

Yes

Replace the instrument panel cluster.

Note

- Perform programming after replacing the instrument panel cluster.

Refer to "9.Body, Cab, Accessories 9E.Instrumentation, Driver Info. instrument panel cluster removal".

Refer to "9.Body, Cab, Accessories 9E.Instrumentation, Driver Info. instrument panel cluster installation".

Refer to "9.Body, Cab, Accessories 9E.Instrumentation, Driver Info. instrument panel cluster setting".

No

Write the vehicle information into the instrument panel cluster.

Refer to "9.Body, Cab, Accessories 9E.Instrumentation, Driver Info. instrument panel cluster setting".

4. DPD components inspection

1) Inspect the exhaust differential pressure sensor for the following. Is the result normal?

- Incorrect piping or disconnection of the differential pressure hose or pipe

- Clogging, collapsing, or twisting of the differential pressure hose or pipe

- Incorrect installation of the exhaust differential pressure sensor

- Exhaust differential pressure sensor damage

- Dirt or foreign material blocking the inlet of the exhaust differential pressure sensor

- Misdetection or delayed response of the exhaust differential pressure sensor

Note

- The installation direction of the differential pressure hose is predetermined.

Refer to "1.Engine 1Z.Engine Electrical Control(4JJ3 with DPD) exhaust differential pressure sensor removal".

2) Inspect the exhaust system for the following conditions. Is the result normal?

- Missing or damaged exhaust pipe gasket

- Exhaust gas leakage from the exhaust pipe, gasket, DPD body, exhaust gas temperature sensor, or differential pressure hose or pipe

- Exhaust system modification

- Misdetection or delayed response of the exhaust gas temperature sensor

3) Inspect the air intake system for the following conditions. Is the result normal?

- Clogged air cleaner element, collapsing of the air intake piping between the air cleaner and inlet cover, or a state where flow is restricted

- Air intake system modification

- Leakage in the air intake system

- Dirt or foreign material blocking the inlet of the MAF sensor

- Misdetection or delayed response of the MAF sensor

4) Are all of the results normal?

Yes

=>Go to DPD status verification.

No

Repair or replace as necessary.

Note

- If the exhaust differential pressure sensor is replaced, learning must be performed.

Refer to "1.Engine 1Z.Engine Electrical Control(4JJ3 with DPD) exhaust differential pressure sensor installation".

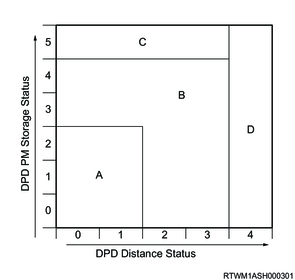

5. DPD status verification

1) Observe the DPD PM Storage Status parameter and the DPD Distance Status parameter on the scan tool. Does it apply to the A or B area in the DPD status table?

- Range A: Normal range

- Range B: If the DPD operator regeneration light flashes, DPD regeneration is requested when running at a high speed.

- Range C: Exhaust differential pressure is excessively high, and DPD regeneration is inhibited.

- Range D: Distance status value is abnormal, and DPD regeneration is inhibited.

Yes

=>Go to DPD Forced Regeneration.

No

6. DPD Forced Regeneration

1) Perform the clearing of the DTC and DPD Regeneration Data Reset with a scan tool.

Refer to "1.Engine 1G.Exhaust(4JJ3 with DPD) DPD installation".

2) Turn OFF the ignition switch for 1 minute or more.

3) Perform DPD Forced Regeneration with a scan tool.

DPD regeneration is completed normally.

=>Go to DPD exhaust differential pressure check.

DPD regeneration is not started.

The ECM does not permit DPD regeneration control. Refer to If DPD regeneration is not started under Functional description.

DPD regeneration is not completed.

=>Go to DPD-related DTC check.

7. DPD inspection

1) Perform Exhaust Differential Pressure Sensor Learning.

Refer to "1.Engine 1G.Exhaust(4JJ3 with DPD) DPD installation".

2) Perform the clearing of the DTC and DPD Regeneration Data Reset with a scan tool.

Refer to "1.Engine 1G.Exhaust(4JJ3 with DPD) DPD installation".

3) Turn OFF the ignition switch for 1 minute or more.

4) Start the engine.

5) Observe the Exhaust Gas Temperature 1 parameter on the scan tool.

Value: 170 ℃ { 338 °F }

6) If the reading is more than the specified value, run the engine at 1,500 rpm with no load until the temperature is lowered to reach the specified value.

7) Observe the Exhaust Differential Pressure parameter when the Exhaust Gas Temperature 1 parameter reaches the specified value with the accelerator pedal fully depressed. Is the Exhaust differential pressure parameter less than or equal to the specified value?

Value: 190 ℃ { 374 °F } Exhaust Gas Temperature 1

Value: 28.0 kPa { 4.1 psi } Exhaust Differential Pressure

Yes

=>Go to DPD Forced Slow Regeneration.

No

Replace the DPD.

Note

- If a DTC is set, clear the DTC with a scan tool.

Refer to "1.Engine 1G.Exhaust(4JJ3 with DPD) DPD removal".

Refer to "1.Engine 1G.Exhaust(4JJ3 with DPD) DPD installation".

Note

- After replacing the DPD, observe the DTC information with a scan tool.

8. DPD Forced Slow Regeneration

1) Turn ON the ignition switch.

2) If a DTC is set, clear the DTC with a scan tool.

3) Turn OFF the ignition switch for 1 minute or more.

4) Perform the DPD Slow Regeneration with a scan tool.

Caution

- To prevent heat from accumulating in the underfloor, perform work in a well-ventilated area or use an electric fan, etc., to blow air into the underfloor.

- Open the engine hood to allow heat to leave the engine room.

- After completing DPD Slow Regeneration, do not turn OFF the engine immediately. Idle the engine for at least 15 minutes and then turn OFF the engine.

- After completing the DPD Slow Regeneration, do not continue to perform regeneration. Wait at least 30 minutes.

- After completing the DPD Slow Regeneration, be sure to replace the engine oil.

DPD regeneration is completed normally.

=>Go to DPD exhaust differential pressure check.

DPD regeneration is not started.

The ECM does not permit DPD regeneration control. Refer to If DPD regeneration is not started under Functional description.

DPD regeneration is not completed.

=>Go to DPD-related DTC check.

9. DPD-related DTC check

1) Observe the DPD-related DTC information on the scan tool. Is DPD-related DTC set?

Yes

Go to the applicable DTC diagnosis.

No

=>Go to Exhaust system, cooling system, and fuel system checks.

10. Exhaust system, cooling system, and fuel system checks

1) Remove the DPD.

Refer to "1.Engine 1G.Exhaust(4JJ3 with DPD) DPD removal".

2) Inspect the DPD for damage, cracking, or melting.

3) Inspect the engine cooling system for causes of overheating.

4) Inspect the fuel system problem.

Refer to "1.Engine 1C.Fuel System(4JJ3 with DPD) fuel inspection".

5) Repair or replace as necessary.

Procedure completion

11. DPD exhaust differential pressure check

1) Perform Exhaust Differential Pressure Sensor Learning.

Refer to "1.Engine 1G.Exhaust(4JJ3 with DPD) DPD installation".

2) Observe the Exhaust Gas Temperature 1 parameter on the scan tool.

Value: 170 ℃ { 338 °F }

3) If the reading is more than the specified value, run the engine at 1,500 rpm with no load until the temperature is lowered to reach the specified value.

4) Observe the Exhaust Differential Pressure parameter when the Exhaust Gas Temperature 1 parameter reaches the specified value with the accelerator pedal fully depressed.

Value: 190 ℃ { 374 °F } Exhaust Gas Temperature 1

Value: 1.1 to 16.0 kPa { 0.2 to 2.3 psi } Exhaust Differential Pressure

The reading is more than the specified value.

Replace the DPD.

Refer to "1.Engine 1G.Exhaust(4JJ3 with DPD) DPD removal".

Refer to "1.Engine 1G.Exhaust(4JJ3 with DPD) DPD installation".

The reading is within the specified range.

The system is normal.

The reading is less than the specified value.

Inspect the cause of the low exhaust differential pressure while referring to DTC P2002.

Refer to "51.Engine Control 1A.Troubleshooting(4JJ3 with DPD) DTC P2002 Particulate Trap Efficiency Below Threshold".

12. Repair verification

1) Reconnect all of the disconnected harness connectors and components.

2) Turn OFF the ignition switch for 1 minute or more.

Procedure completion

=>Go to Instrument panel cluster display illumination check.