|

ac5wzw00012876

DTC P3102:00, P3104:00, P3106:00, P3108:00 [PCM (SKYACTIV-D 2.2)]

id0102j5736600

Details On DTCs

|

DESCRIPTION |

Fuel injection amount correction control malfunction between cylinders: • P3102:00: Fuel injection correction amount of cylinder No.1 is too little

• P3104:00: Fuel injection correction amount of cylinder No.2 is too little

• P3106:00: Fuel injection correction amount of cylinder No.3 is too little

• P3108:00: Fuel injection correction amount of cylinder No.4 is too little

|

|

|---|---|---|

|

DETECTION CONDITION

|

Determination conditions

|

• The PCM detects that the FCCB(Fuel Compensation for Cylinders Balancing) correction amount reaches the lower limit during the specified rotation..

|

|

Preconditions

|

• Fuel-cut control is not implemented.

• The following DTCs are not detected:

|

|

|

Malfunction determination period

|

• 58,320 deg CA (Accumulate)

|

|

|

Drive cycle

|

• 2

|

|

|

Self test type

|

• CMDTC self test

|

|

|

Sensor used

|

• Fuel injector No.1

• Fuel injector No.2

• Fuel injector No.3

• Fuel injector No.4

• CKP sensor

• ECT sensor No.1

• CMP sensor

• APP sensor

• Fuel pressure sensor/fuel temperature sensor No.2 (built-into fuel injector No.2)

• Fuel pressure sensor/fuel temperature sensor No.3 (built-into fuel injector No.3)

|

|

|

FAIL-SAFE FUNCTION

|

• Not applicable

|

|

|

VEHICLE STATUS WHEN DTCs ARE OUTPUT

|

• Illuminates check engine light.

|

|

|

POSSIBLE CAUSE

|

• ECT sensor No.1 signal malfunction

• IAT sensor No.1 signal malfunction

• MAF sensor signal malfunction

• CKP sensor signal malfunction

• CMP sensor signal malfunction

• APP sensor signal malfunction

• A/F sensor signal malfunction

• EGR valve position sensor signal malfunction

• EGR cooler bypass valve position sensor signal malfunction

• VSS malfunction

• Fuel injector No.1 malfunction

• Fuel injector No.2 malfunction

• Fuel injector No.3 malfunction

• Fuel injector No.4 malfunction

• Fuel injector No.1 connector or terminals malfunction

• Fuel injector No.2 connector or terminals malfunction

• Fuel injector No.3 connector or terminals malfunction

• Fuel injector No.4 connector or terminals malfunction

• PCM connector or terminals malfunction

• Short to ground in wiring harness between the following terminals:

• Short to power supply in wiring harness between the following terminals:

• Fuel injector No.1 circuits are shorted to each other

• Fuel injector No.2 circuits are shorted to each other

• Fuel injector No.3 circuits are shorted to each other

• Fuel injector No.4 circuits are shorted to each other

• Open circuit in wiring harness between the following terminals:

• Air suction in intake air system

• MAF sensor malfunction

• CMP sensor malfunction

• CKP sensor malfunction

• CKP sensor pulse wheel malfunction

• Fuel system malfunction

• Fuel pressure sensor No.2 (built-into fuel injector No.2) malfunction

• Fuel pressure sensor No.3 (built-into fuel injector No.3) malfunction

• Turbocharger malfunction

• Poor fuel quality

• PCM malfunction

|

|

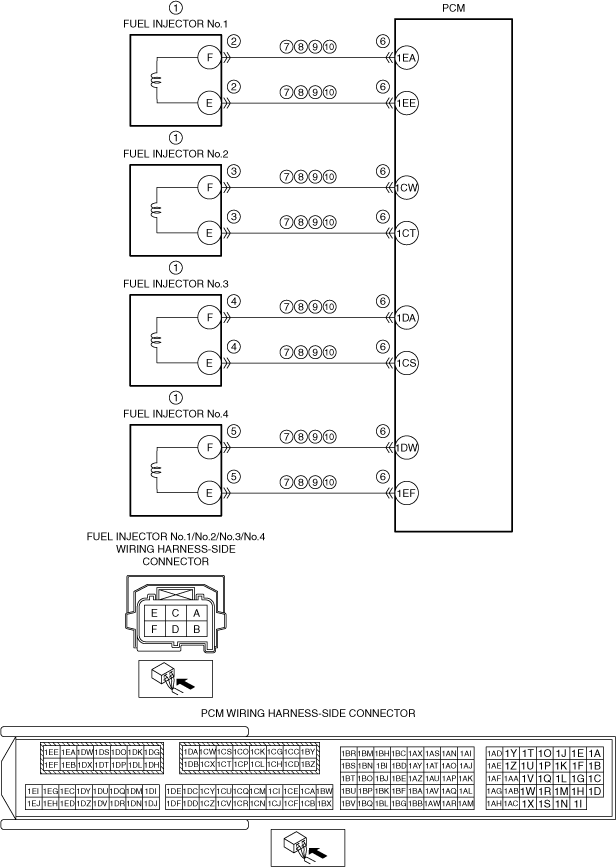

System Wiring Diagram

ac5wzw00012876

|

Function Explanation (DTC Detection Outline)

Repeatability Verification Procedure

PID Item/Simulation Item Used In Diagnosis

PID/DATA monitor item table

|

Item

|

Definition

|

Unit

|

Condition/Specification

|

|

APP

|

Accelerator pedal position

|

%

|

• Accelerator pedal released: Approx. 0%

• Accelerator pedal fully depressed: Approx. 100%

|

|

ECT

|

Engine coolant temperature

|

°C, °F

|

• Displays the ECT.

|

|

EGR_C_BP_ACT

|

Actual measured EGR cooler bypass valve opening angle

|

%

|

ECT: above 70 °C {158 °F}

• Idle: Approx. 0 % (after 20—30 s have elapsed since start the engine)

• Racing (engine speed 2,000 rpm): 0 %

|

|

EGRP_ACT

|

EGR valve actual opening angle

|

%

|

ECT: above 70 °C {158 °F}

• Idle: Approx. 0 % (after 20—30 s have elapsed since start the engine)

• Racing (engine speed 2,000 rpm): Approx. 60 %

|

|

IAT

|

Intake air temperature (No.1)

|

°C, °F

|

• Displays the intake air temperature (No.1).

|

|

MAF

|

Mass air flow

|

g/sec

|

• Switch the ignition ON (engine off): Approx. 1.00 g/s {0.132 lb/min}

• Idle: Approx. 5.47 g/s {0.724 lb/min}

• Racing (engine speed 2,000 rpm): Approx. 13.84 g/s {1.831 lb/min}

• Racing (engine speed 4,000 rpm): Approx. 85.13 g/s {11.26 lb/min}

|

|

O2S11

|

A/F sensor current

|

µA

|

• Idle: Approx. 1.01 mA

• Deceleration fuel cut: Approx. 3.84 mA

|

|

A/F sensor voltage

|

V

|

• Switch ignition ON (engine off): 3.24 V

• Deceleration fuel cut: Approx. 3.74 V

|

|

|

RPM

|

Engine speed

|

RPM

|

• Displays the engine speed.

|

|

VSS

|

Vehicle speed

|

KPH, MPH

|

• Displays the vehicle speed.

|

Function Inspection Using M-MDS

|

STEP |

INSPECTION |

RESULTS |

ACTION |

|---|---|---|---|

|

1

|

PURPOSE: VERIFY RELATED REPAIR INFORMATION AVAILABILITY

• Verify related Service Bulletins and/or on-line repair information availability.

• Is any related repair information available?

|

Yes

|

Perform repair or diagnosis according to the available repair information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

||

|

2

|

PURPOSE: IDENTIFY TRIGGER DTC FOR FREEZE FRAME DATA

• Is the DTC P3102:00, P3104:00, P3106:00 or P3108:00 on FREEZE FRAME DATA?

|

Yes

|

Go to the next step.

|

|

No

|

Go to the troubleshooting procedure for DTC on FREEZE FRAME DATA.

|

||

|

3

|

PURPOSE: RECORD VEHICLE STATUS AT TIME OF DTC DETECTION TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the FREEZE FRAME DATA/snapshot data on the repair order.

|

—

|

Go to the next step.

|

|

4

|

PURPOSE: VERIFY IF THERE IS PID ITEM CAUSING DRASTIC CHANGES OF ACCELERATION FLUCTUATION BY INPUT SIGNAL TO PCM

• Access the following PIDs using the M-MDS:

• Is there any signal that is far out of specification?

|

Yes

|

Go to the next step.

|

|

No

|

Go to the troubleshooting procedure to perform the procedure from Step 1.

|

||

|

5

|

PURPOSE: VERIFY CONNECTOR CONNECTIONS

• Access the following PIDs using the M-MDS:

• When the following parts are shaken, does the PID value include a PID item which has changed?

|

Yes

|

Inspect the related wiring harness and connector.

• Repair or replace the malfunctioning part.

Go to the troubleshooting procedure to perform the procedure from Step 20.

|

|

No

|

Go to the troubleshooting procedure to perform the procedure from Step 1.

|

Troubleshooting Diagnostic Procedure

|

STEP |

INSPECTION |

RESULTS |

ACTION |

|---|---|---|---|

|

1

|

PURPOSE: DETERMINE INTEGRITY OF FUEL INJECTOR No.1—No.4

• Inspect the fuel injector No.1—No.4.

• Is there any malfunction?

|

Yes

|

Replace the suspected fuel injector, then go to Step 20.

|

|

No

|

Go to the next step.

|

||

|

2

|

PURPOSE: INSPECT FUEL INJECTOR No.1 CONNECTOR CONDITION

• Switch the ignition off.

• Disconnect the fuel injector No.1 connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then go to Step 20.

|

|

No

|

Go to the next step.

|

||

|

3

|

PURPOSE: INSPECT FUEL INJECTOR No.2 CONNECTOR CONDITION

• Disconnect the fuel injector No.2 connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then go to Step 20.

|

|

No

|

Go to the next step.

|

||

|

4

|

PURPOSE: INSPECT FUEL INJECTOR No.3 CONNECTOR CONDITION

• Disconnect the fuel injector No.3 connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then go to Step 20.

|

|

No

|

Go to the next step.

|

||

|

5

|

PURPOSE: INSPECT FUEL INJECTOR No.4 CONNECTOR CONDITION

• Disconnect the fuel injector No.4 connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then go to Step 20.

|

|

No

|

Go to the next step.

|

||

|

6

|

PURPOSE: INSPECT PCM CONNECTOR CONDITION

• Disconnect the PCM connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then go to Step 20.

|

|

No

|

Go to the next step.

|

||

|

7

|

PURPOSE: INSPECT FUEL INJECTOR CIRCUIT FOR SHORT TO GROUND

• Verify that the fuel injector No.1, No.2, No.3, No.4 and PCM connectors are disconnected.

• Inspect for continuity between the following terminals (wiring harness-side) and body ground:

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• Fuel injector No.1 terminal F—PCM terminal 1EA

• Fuel injector No.1 terminal E—PCM terminal 1EE

• Fuel injector No.2 terminal F—PCM terminal 1CW

• Fuel injector No.2 terminal E—PCM terminal 1CT

• Fuel injector No.3 terminal F—PCM terminal 1DA

• Fuel injector No.3 terminal E—PCM terminal 1CS

• Fuel injector No.4 terminal F—PCM terminal 1DW

• Fuel injector No.4 terminal E—PCM terminal 1EF

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to ground.

Go to Step 20.

|

|

No

|

Go to the next step.

|

||

|

8

|

PURPOSE: INSPECT FUEL INJECTOR CIRCUIT FOR SHORT TO POWER SUPPLY

• Verify that the fuel injector No.1, No.2, No.3, No.4 and PCM connectors are disconnected.

• Switch the ignition ON (engine off).

• Measure the voltage at the following terminals (wiring harness-side):

• Is the voltage 0 V?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• Fuel injector No.1 terminal F—PCM terminal 1EA

• Fuel injector No.1 terminal E—PCM terminal 1EE

• Fuel injector No.2 terminal F—PCM terminal 1CW

• Fuel injector No.2 terminal E—PCM terminal 1CT

• Fuel injector No.3 terminal F—PCM terminal 1DA

• Fuel injector No.3 terminal E—PCM terminal 1CS

• Fuel injector No.4 terminal F—PCM terminal 1DW

• Fuel injector No.4 terminal E—PCM terminal 1EF

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to power supply.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to power supply.

Go to Step 20.

|

||

|

9

|

PURPOSE: INSPECT FUEL INJECTOR CIRCUITS FOR SHORT TO EACH OTHER

• Verify that the fuel injector No.1, No.2, No.3, No.4 and PCM connectors are disconnected.

• Switch the ignition off.

• Inspect for continuity between the following terminals (wiring harness-side):

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• Fuel injector No.1 terminal F—PCM terminal 1EA

• Fuel injector No.1 terminal E—PCM terminal 1EE

• Fuel injector No.2 terminal F—PCM terminal 1CW

• Fuel injector No.2 terminal E—PCM terminal 1CT

• Fuel injector No.3 terminal F—PCM terminal 1DA

• Fuel injector No.3 terminal E—PCM terminal 1CS

• Fuel injector No.4 terminal F—PCM terminal 1DW

• Fuel injector No.4 terminal E—PCM terminal 1EF

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to each other.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to each other.

Go to Step 20.

|

|

No

|

Go to the next step.

|

||

|

10

|

PURPOSE: INSPECT FUEL INJECTOR CIRCUIT FOR OPEN CIRCUIT

• Verify that the fuel injector No.1, No.2, No.3, No.4 and PCM connectors are disconnected.

• Inspect for continuity between the following terminals (wiring harness-side):

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• Fuel injector No.1 terminal F—PCM terminal 1EA

• Fuel injector No.1 terminal E—PCM terminal 1EE

• Fuel injector No.2 terminal F—PCM terminal 1CW

• Fuel injector No.2 terminal E—PCM terminal 1CT

• Fuel injector No.3 terminal F—PCM terminal 1DA

• Fuel injector No.3 terminal E—PCM terminal 1CS

• Fuel injector No.4 terminal F—PCM terminal 1DW

• Fuel injector No.4 terminal E—PCM terminal 1EF

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Go to Step 20.

|

||

|

11

|

PURPOSE: VERIFY IF MALFUNCTION RELATED TO INTAKE AIR SYSTEM AFFECTS DIAGNOSTIC RESULTS

• Visually inspect for loose, cracked or damaged hoses on intake air system.

• Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results, then go to Step 20.

|

|

No

|

Go to the next step.

|

||

|

12

|

PURPOSE: INSPECT MAF SENSOR

• Reconnect all disconnected connectors.

• Inspect the MAF sensor.

• Is there any malfunction?

|

Yes

|

Replace the MAF sensor/IAT sensor No.1, then go to Step 20.

|

|

No

|

Go to the next step.

|

||

|

13

|

PURPOSE: INSPECT CMP SENSOR

• Inspect the CMP sensor.

• Is there any malfunction?

|

Yes

|

Replace the CMP sensor, then go to Step 20.

|

|

No

|

Go to the next step.

|

||

|

14

|

PURPOSE: INSPECT CKP SENSOR

• Inspect the CKP sensor.

• Is there any malfunction?

|

Yes

|

Replace the CKP sensor, then go to Step 20.

|

|

No

|

Go to the next step.

|

||

|

15

|

PURPOSE: INSPECT CKP SENSOR PULSE WHEEL

• Visually inspect the CKP sensor pulse wheel.

• Are there any damage or scratches at the CKP sensor pulse wheel?

|

Yes

|

Replace the CKP sensor pulse wheel, then go to Step 20.

|

|

No

|

Go to the next step.

|

||

|

16

|

PURPOSE: INSPECT FOR FUEL LEAKAGE FROM FUEL SYSTEM

• Visually inspect the following:

• Are all items normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning part according to the inspection results, then go to Step 20.

|

||

|

17

|

PURPOSE: INSPECT FUEL INJECTION RELATED PARTS

• Inspect the following parts:

• Are all items normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning part according to the inspection results, then go to Step 20.

|

||

|

18

|

PURPOSE: INSPECT FUEL PRESSURE SENSOR

• Inspect the fuel pressure sensor No.2 and fuel pressure sensor No.3.

• Is there any malfunction?

|

Yes

|

Replace the fuel pressure sensor No.2 and/or fuel pressure sensor No.3, then go to Step 20.

|

|

No

|

Go to the next step.

|

||

|

19

|

PURPOSE: INSPECT TURBOCHARGER

• Inspect the turbocharger.

• Is there any malfunction?

|

Yes

|

Replace the turbocharger, then go to the next step.

|

|

No

|

Go to the next step.

|

||

|

20

|

PURPOSE: VERIFICATION OF VEHICLE REPAIR COMPLETION

• Always reconnect all disconnected connectors.

• Clear the DTC from the PCM memory using the M-MDS.

• Implement the repeatability verification procedure.

• Perform the Pending Trouble Code Access Procedure.

• Is the PENDING CODE for this DTC present?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the PCM.

Go to the next step.

|

|

No

|

Go to the next step.

|

||

|

21

|

PURPOSE: VERIFY IF THERE IS ANY OTHER MALFUNCTION

• Is any other DTC or pending code stored?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

DTC troubleshooting completed.

|