|

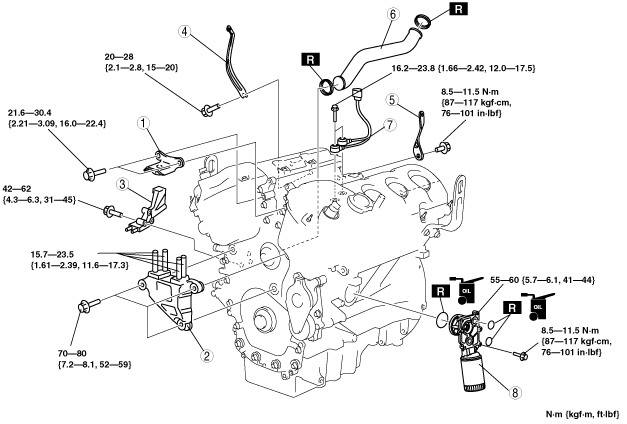

ENGINE DISASSEMBLY/ASSEMBLY [MZI-3.7]

id0110c5800500

1. Remove the transaxle from the engine. (See AUTOMATIC TRANSAXLE REMOVAL/INSTALLATION [AW6A-EL, AW6AX-EL].)

2. Remove the drive plate. (See DRIVE PLATE REMOVAL/INSTALLATION [AW6A-EL, AW6AX-EL].)

3. Remove the ignition coils. (See IGNITION COIL REMOVAL/INSTALLATION [MZI-3.7].)

4. Remove the CMP sensor. (See CAMSHAFT POSITION (CMP) SENSOR REMOVAL/INSTALLATION [MZI-3.7].)

5. Remove the power steering oil pump. (See POWER STEERING OIL PUMP REMOVAL/INSTALLATION [L.H.D.].)(See POWER STEERING OIL PUMP REMOVAL/INSTALLATION [R.H.D.].)

6. Remove the generator. (See GENERATOR REMOVAL/INSTALLATION [MZI-3.7].)

7. Remove the fuel injector and fuel distributor. (See FUEL INJECTOR REMOVAL/INSTALLATION [MZI-3.7].)

8. Remove the intake-air system. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [MZI-3.7].)

9. Remove the exhaust system. (See EXHAUST SYSTEM REMOVAL/INSTALLATION [MZI-3.7].)

10. Remove the thermostat case and water hose component. (See THERMOSTAT REMOVAL/INSTALLATION [MZI-3.7].)

11. Remove the CHT sensor. (See CYLINDER HEAD TEMPERATURE (CHT) SENSOR REMOVAL/INSTALLATION [MZI-3.7].)

12. Remove the CKP sensor. (See CRANKSHAFT POSITION (CKP) SENSOR REMOVAL/INSTALLATION [MZI-3.7].)

13. Remove the oil pressure switch. (See OIL PRESSURE INSPECTION [MZI-3.7].)

14. Remove the oil cooler. (See OIL COOLER REMOVAL/INSTALLATION [MZI-3.7].)

15. Disassemble in the order indicated in the table.

16. Assemble in the reverse order of disassembly.

ac9wzw00002249

|

|

1

|

No.3 engine mount stay (engine front cover side) (If equipped)

|

|

2

|

No.3 engine mount bracket

|

|

3

|

Transfer bracket

|

|

4

|

Dynamic chamber bracket (engine right side)

|

|

5

|

Dynamic chamber bracket (engine back side)

|

|

6

|

Water inlet pipe

|

|

7

|

KS

|

|

8

|

Oil filter adapter and oil filter

|

No.3 Engine Mount Stay (Engine Front Cover Side) Installation Note

1. Tighten the No.3 engine mount stay (engine front cover side) in the order shown in the figure.

ac9wzw00002250

|

Water Inlet Pipe Installation Note

1. Apply clean engine coolant to the O-ring.