|

VEHICLE SPEED SENSOR (VSS) REMOVAL/INSTALLATION [AY6A-EL, AY6AX-EL]

id0517k3299000

1. Drain the ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [AY6A-EL, AY6AX-EL].)

2. Remove the transaxle. (See AUTOMATIC TRANSAXLE REMOVAL/INSTALLATION [AY6A-EL, AY6AX-EL].)

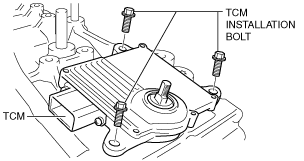

3. Remove the TCM.

ac9uuw00003976

|

ac9uuw00001971

|

4. Inspect the condition of the connector pin of the coupler component (foreign material, bent pins, broken pins) and O-ring after the TCM is removed.

am6xuw00004289

|

5. Remove the O-ring from the coupler component.

am6xuw00004290

|

6. Clean the transaxle. (See AUTOMATIC TRANSAXLE CLEANING [AY6A-EL, AY6AX-EL].)

7. Remove the torque converter. (See TORQUE CONVERTER REMOVAL/INSTALLATION [AY6A-EL, AY6AX-EL].)

8. Remove the stud bolts.

ac9uuw00004107

|

9. Set the SSTs as shown in the figure.

ac9wzw00002030

|

10. Install the transaxle to the SSTs.

ac9wzw00002032

|

11. Remove the oil pipe component and the O-rings.

ac9uuw00004108

|

12. Refer to the “AUTOMATIC TRANSAXLE DISASSEMBLY/ASSEMBLY PRECAUTION” before disassembling/assembling the transaxle. (See AUTOMATIC TRANSAXLE DISASSEMBLY/ASSEMBLY PRECAUTION [AY6A-EL, AY6AX-EL].)

13. Remove the control valve body cover.

am6xuw00004095

|

14. Using a plastic hammer, tap the control valve body cover to remove it.

ac9uuw00003980

|

ac9uuw00003981

|

ac9uuw00003982

|

15. Disconnect the solenoid connectors, VSS connector and the input/turbine speed sensor connector.

ac9uuw00003983

|

16. Disconnect the coupler component from the clamp.

ac9uuw00004109

|

17. Remove the lock plate, and pull out the TFT sensor from the control valve body.

ac9uuw00003984

|

18. Remove the VSS connector from the solenoid clamp.

ac9uuw00003985

|

19. Remove the suction cover and the gasket.

ac9uuw00003986

|

20. Remove the control valve body installation bolts in the order shown in the figure.

ac9uuw00003987

|

21. Disconnect the manual valve link and remove the control valve body component.

ac9uuw00003988

|

22. Fix the coupler component with tape to the transaxle case as shown in the figure.

am6xuw00005027

|

23. Fix the VSS wiring harness with tape to the transaxle case as shown in the figure.

am6xuw00005028

|

24. Remove the converter housing. (See CONVERTER HOUSING REMOVAL/INSTALLATION [AY6A-EL, AY6AX-EL].)

25. Remove the oil pump component and oil strainer as a single unit. (See OIL PUMP REMOVAL/INSTALLATION [AY6A-EL, AY6AX-EL].)

26. Remove the C3 clutch component, front planetary gear component and input shaft.

am6xuw00004063

|

27. Remove the C3 clutch component from the front planetary gear component and input shaft.

am6xuw00004064

|

28. Remove the brake band anchor bolt.

am6xuw00004065

|

29. Remove the B1 brake band.

am6xuw00004066

|

30. Remove the thrust bearing, bearing race and the C1 clutch component.

am6xuw00004067

|

31. Remove the thrust bearing, bearing race and the sun gear input drum.

am6xuw00004068

|

32. Remove the detent spring cover and detent spring.

am6xuw00004069

|

33. Remove the pawl return spring and the parking pawl shaft.

am6xuw00004070

|

34. Remove the torsion spring and the spring guide sleeve.

ac9uuw00004110

|

35. Remove the parking pawl and the parking pawl bracket.

am6xuw00004072

|

36. Disconnect the parking rod from the manual valve lever.

am6xuw00004073

|

37. Remove the manual valve lever from the transaxle case.

am6xuw00004074

|

38. Remove the parking rod from the transaxle case.

am6xuw00004075

|

39. Remove the parking pin from the transaxle case.

am6xuw00004076

|

40. Remove the counter gear component.

ac9uuw00004149

|

41. Remove the differential component.

am6xuw00004078

|

42. Disconnect the VSS wiring harness from the wiring harness clip.

am6xuw00004079

|

43. Remove the pipe clamp, transaxle case No.1 plate, wiring harness clip and the oil cooler outlet tube.

am6xuw00004080

|

44. Remove the O-rings from the oil cooler outlet tube.

ac9wzw00001937

|

45. Using a flathead screwdriver and a hammer, pry back the crimp on the lockwashers.

ac9uuw00004112

|

46. Remove the lockwashers, washers and the counter drive gear.

ac9uuw00004113

|

47. Remove the VSS and spacer from the counter drive gear.

am6xuw00004083

|

48. Install the VSS and spacer to the counter drive gear.

am6xuw00004083

|

49. Apply ATF to the spline on the counter drive gear and spline on the ring gear.

50. Install the counter drive gear to the transaxle case.

51. Install the lockwashers and washers with bolts.

am6xuw00004084

|

52. Using a flathead screwdriver and a hammer, pry back the crimp locking the lockwashers.

ac9uuw00003991

|

53. Apply ATF to the new O-rings.

O-ring size

|

Inner diameter (mm {in}) |

Thickness (mm {in}) |

|---|---|

|

9.8 {0.39}

|

1.9 {0.075}

|

54. Install the new O-rings to the oil cooler outlet tube.

ac9wzw00001937

|

55. Install the oil cooler outlet tube, pipe clamp, transaxle case No.1 plate and the wiring harness clip to the converter housing.

am6xuw00004080

|

56. Connect the VSS wiring harness to the wiring harness clip.

am6xuw00004079

|

57. Apply ATF to the bearing and gear of the differential component.

58. Install the differential component to the transaxle case.

am6xuw00004078

|

59. Apply ATF to the bearing and gear of the counter gear component.

60. Install the counter gear component to the transaxle case.

ac9uuw00004149

|

61. Install the parking pin to the transaxle case.

am6xuw00004076

|

62. Insert the parking rod to the transaxle case.

am6xuw00004075

|

63. Install the manual valve lever to the transaxle case.

am6xuw00004085

|

64. Connect the parking rod to the manual valve lever.

am6xuw00004073

|

65. Install the parking pawl, parking pawl bracket and the parking rod to the transaxle case.

am6xuw00004086

|

66. Install the spring guide sleeve and the torsion spring.

am6xuw00004071

|

67. Install the pawl return spring to the parking pawl shaft.

68. Install the pawl return spring and the parking pawl shaft to the transaxle case.

am6xuw00004070

|

69. Install the detent spring cover and detent spring to the transaxle case.

am6xuw00004069

|

ac9uuw00004115

|

70. Install the sun gear input drum to the transaxle case.

ac9uuw00004082

|

71. Apply ATF to the bearing race and the thrust bearing.

72. Install the bearing race and thrust bearing to the transaxle case as shown in the figure.

ac9uuw00004116

|

73. Install the C1 clutch component to the transaxle case.

ac9uuw00004084

|

74. Apply ATF to the bearing race and the thrust bearing.

75. Install the bearing race and thrust bearing to the transaxle case as shown in the figure.

ac9uuw00004117

|

76. Install the front planetary gear component and input shaft to the transaxle case.

ac9uuw00004118

|

77. Apply ATF to the bushing of the C3 clutch component.

78. Install the C3 clutch component to the transaxle case.

ac9uuw00004119

|

am6xuw00004090

|

79. Install the B1 brake band to the transaxle case.

am6xuw00004091

|

80. Install the brake band anchor bolt to the transaxle case.

am6xuw00004065

|

81. Install the oil pump component and oil strainer as a single unit. (See OIL PUMP REMOVAL/INSTALLATION [AY6A-EL, AY6AX-EL].)

82. Install the converter housing. (See CONVERTER HOUSING REMOVAL/INSTALLATION [AY6A-EL, AY6AX-EL].)

83. Connect the manual valve link and install the control valve body component.

ac9uuw00004210

|

84. Temporarily install the control valve body component with the bolts.

ac9uuw00003993

|

85. Temporarily install the suction cover and a new gasket with the bolts.

ac9uuw00003986

|

86. Tighten the bolts in the order shown in the figure.

ac9uuw00003994

|

87. Install the connector of the VSS to the solenoid clamp.

ac9uuw00003985

|

88. Install the TFT sensor with the lock plate and a bolt to the control valve body component as shown in the figure.

ac9uuw00003984

|

89. Connect the solenoid connectors, VSS connector and the input/turbine speed sensor connector.

ac9uuw00003983

|

90. Connect the coupler component to the clamps.

ac9uuw00004109

|

91. Clean sealant and oil off the contact surface of the transaxle case with the control valve body cover and the bolt holes.

ac9uuw00003995

|

92. Clean oil off the contact surface of the new control valve body cover with the transaxle case.

93. Apply sealant to the new control valve body cover as shown in the figure.

am6xuw00004155

|

94. Install the new control valve body cover with new seal bolts before the applied sealant starts to harden.

am6xuw00004095

|

95. Install the oil pipe component and new O-rings.

ac9uuw00004108

|

96. Install a new O-ring to the coupler component.

am6xuw00004290

|

97. Align the transaxle case and coupler component connector.

ac9uuw00003937

|

98. Be sure to match the position of the TCM marking.

am6xuw00004123

|

99. Install the TCM.

100. Verify the correct positioning of the TCM and coupler component.

am6xuw00004124

|

101. Tighten the TCM installation bolts.

ac9uuw00003996

|

102. Remove the transaxle from the SSTs.

ac9wzw00002033

|

103. Install the stud bolts using double nutted.

ac9uuw00003997

|

104. Remove the double nutted from the stud bolts.

105. Install the torque converter. (See TORQUE CONVERTER REMOVAL/INSTALLATION [AY6A-EL, AY6AX-EL].)

106. Install the transaxle. (See AUTOMATIC TRANSAXLE REMOVAL/INSTALLATION [AY6A-EL, AY6AX-EL].)

107. Add ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) LEVEL ADJUSTMENT [AY6A-EL, AY6AX-EL].)

108. Perform the “TCM NEUTRAL POSITION LEARNING”. (See TCM NEUTRAL POSITION LEARNING [AY6A-EL, AY6AX-EL].)

109. Adjust the ATF level. (See AUTOMATIC TRANSAXLE FLUID (ATF) LEVEL ADJUSTMENT [AY6A-EL, AY6AX-EL].)

110. Perform the “MECHANICAL SYSTEM TEST”. (See MECHANICAL SYSTEM TEST [AY6A-EL, AY6AX-EL].)

111. Perform the “ROAD TEST”. (See ROAD TEST [AY6A-EL, AY6AX-EL].)