|

1

|

VERIFY DASH-ELECTRICAL SUPPLY UNIT DTCs

• Perform the DTC inspection for the dash-electrical supply unit using the M-MDS.

• Is a DTC displayed?

|

Yes

|

Repair the malfunctioning part according to the applicable DTC troubleshooting and perform the repair completion verification.

|

|

No

|

Go to the next step.

|

|

2

|

VERIFY BLOWER MOTOR OPERATION

• Switch the main power ON (READY off or on).

• Set the airflow volume control switch to ON.

• Set the air intake mode to REC.

• Does the blower motor in the blower unit rotate smoothly?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 4.

|

|

3

|

INSPECT BLOWER UNIT FOR CLOGGING

• Is there clogging in the vent of the blower unit?

|

Yes

|

Remove the obstruction, then go to the repair completion verification.

|

|

No

|

Verify that there is no obstruction in the air duct between the blower unit and A/C unit, there is no air filter clogging, and the evaporator is not frosted (frozen), then go to the repair completion verification.

|

|

4*

|

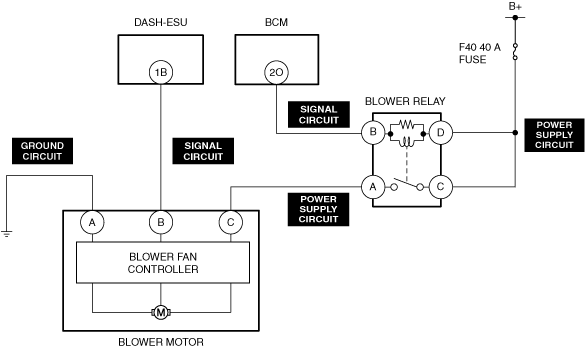

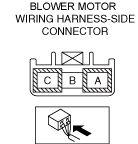

VERIFY BLOWER MOTOR TERMINAL VOLTAGE

• Switch the main power ON (READY off or on).

• Set the airflow volume control dial to 6 or more.

• Measure the voltage at the following terminals.

-

― Blower motor terminal C

• Is the voltage B+?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 10.

|

|

5

|

VERIFY F40 40A FUSE

• Remove the F40 40A fuse.

• Inspect the F40 40A fuse.

• Is the fuse normal?

|

Yes

|

Install the F40 40A fuse, then go to the next step.

|

|

No

|

Replace the F40 40A fuse and perform the repair completion verification.

|

|

6*

|

VERIFY BLOWER RELAY TERMINAL VOLTAGE

• Measure the voltage at the following terminals.

-

― Blower relay terminal C

― Blower relay terminal D

• Is the voltage B+?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the blower relay power supply circuit and perform the repair completion verification.

|

|

7*

|

VERIFY BLOWER RELAY TERMINAL VOLTAGE

• Measure the voltage at the following terminals.

-

― Blower relay terminal B

• Is the voltage 0 V?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 9.

|

|

8*

|

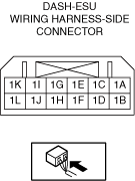

VERIFY BODY CONTROL MODULE (BCM) TERMINAL VOLTAGE

• Measure the voltage at the following terminals.

-

― Body control module (BCM) terminal 2O

• Is the voltage 0 V?

|

Yes

|

Repair or replace the body control module (BCM) signal circuit and perform the repair completion verification.

|

|

No

|

Replace the body control module (BCM) and perform the repair completion verification.

|

|

9*

|

VERIFY BLOWER RELAY TERMINAL VOLTAGE

• Measure the voltage at the following terminals.

-

― Blower relay terminal A

• Is the voltage B+?

|

Yes

|

After replacing the blower relay, perform the repair completion verification.

|

|

No

|

Repair or replace the blower motor power supply circuit and perform the repair completion verification.

|

|

10

|

INSPECT BLOWER MOTOR

• Inspect the applicable parts.

• Is the blower motor normal?

|

Yes

|

Go to the next step.

|

|

No

|

After replacing the blower motor, perform the repair completion verification.

|

|

11

|

INSPECT BLOWER MOTOR SIGNAL CIRCUIT FOR OPEN CIRCUIT AND SHORT TO GROUND

• Inspect the applicable circuit for an open circuit and short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning part and perform the repair completion verification.

|

|

12

|

INSPECT BLOWER MOTOR GROUND CIRCUIT FOR OPEN CIRCUIT AND SHORT TO POWER SUPPLY

• Inspect the applicable circuit for an open circuit and short to power supply.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning part and perform the repair completion verification.

|

|

13

|

VERIFY IF THERE IS OBSTRUCTION IN BLOWER MOTOR FAN ROTATION

• Inspect the blower motor fan in the blower unit.

-

― Is the fan free of interference with the blower unit case?

― Is the fan free of foreign matter and obstructions?

• Is the blower motor fan normal?

|

Yes

|

Replace the dash-electrical supply unit and perform the repair completion verification.

|

|

No

|

Remove the obstruction or repair/replace the blower motor fan, blower unit case, and perform the repair completion verification.

|

|

Repair completion verification

|

VERIFY THAT MALFUNCTION DOES NOT RECUR AFTER REPAIRS

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Has the malfunction symptom been eliminated?

|

Yes

|

Troubleshooting completed. (Explain repair contents to customer.)

|

|

No

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction is not resolved, replace the dash-electrical supply unit.

|