|

1

|

INSPECT POWER SUPPLY

• Access the VPWR PCM PID using the M-MDS.

• Verify the VPWR PID value.

• Is the VPWR PID value B+?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect the following:

• Battery connection

-

― If there is any malfunction:

-

• Repair or replace the malfunctioning location, then repeat this step.

|

|

2

|

DETERMINE IF MALFUNCTION CAUSE IS IMMOBILIZER SYSTEM OR OTHER

• Are any of the following conditions present?

-

― Engine does not start completely.

― PCM DTC P1260:00 is displayed.

|

Yes

|

Both conditions present:

• Go to Step 5.

|

|

No

|

Either or other condition present:

• Go to the next step.

|

|

3

|

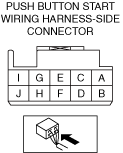

INSPECT PUSH BUTTON START CONNECTOR CONNECTION

• Inspect the connection of push button start connector.

• Is the push button start connector securely connected to the coil antenna?

|

Yes

|

Go to the next step.

|

|

No

|

Reconnect the push button start securely, then repeat from Step 2.

|

|

4

|

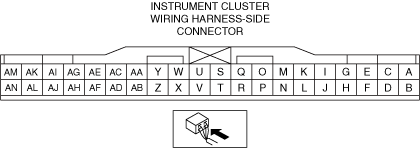

DETERMINE IF MALFUNCTION CAUSE IS INSTRUMENT CLUSTER OR OTHER

• Switch the ignition ON (engine off).

• Does the security indicator light flash?

|

Yes

|

Go to the next step.

|

|

No

|

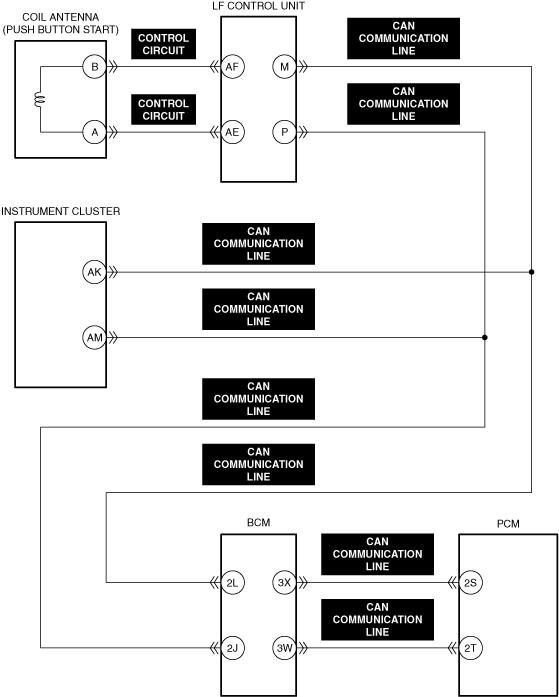

Inspect the wiring harness between the following terminals:

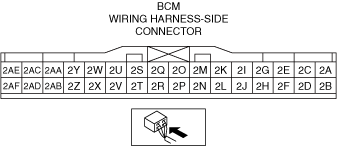

• Instrument cluster terminal AK—Body control module (BCM) terminal 2L

• Instrument cluster terminal AM—Body control module (BCM) terminal 2J

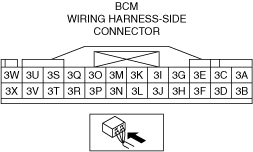

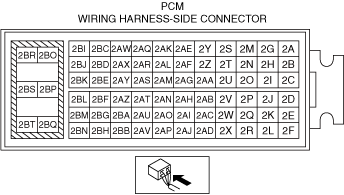

• Body control module (BCM) terminal 3X—PCM terminal 2S

• Body control module (BCM) terminal 3W—PCM terminal 2T

-

― If there is any malfunction:

-

• Repair or replace the malfunctioning location and perform the repair completion verification.

• Inspect the instrument cluster

-

― If there is any malfunction:

-

• Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

5

|

VERIFY IMMOBILIZER SYSTEM (LF CONTROL UNIT) DTC

• Perform the DTC inspection for the body control module (BCM).

• Are any DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

6

|

DETERMINE IF MALFUNCTION CAUSE IS i-stop SYSTEM OR OTHER

• Verify the symptom.

• Does the engine not restart while the i-stop function is operating?

|

Yes

|

Perform the symptom troubleshooting "ENGINE DOES NOT RESTART".

|

|

No

|

Go to the next step.

|

|

7

|

VERIFY PCM DTC

• Perform the DTC inspection for the PCM.

• Are any continuous memory DTCs present?

|

Yes

|

Continuous memory DTC is displayed:

• Repair the malfunctioning location according to the applicable DTC troubleshooting.

Communication error message is displayed:

• Go to the next step.

|

|

No

|

Go to Step 13.

|

|

8

|

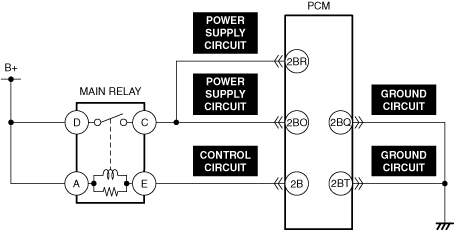

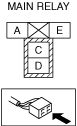

INSPECT MAIN RELAY CONTROL CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

9

|

INSPECT PCM POWER SUPPLY CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

10

|

INSPECT MAIN RELAY FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

11

|

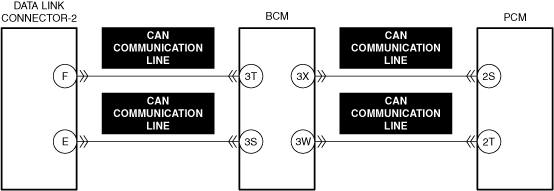

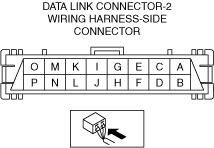

INSPECT CAN COMMUNICATION LINE BETWEEN DLC-2 AND PCM FOR OPEN CIRCUIT

• Inspect the applicable circuit for open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

12

|

INSPECT PCM GROUND CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

13

|

DETERMINE IF MALFUNCTION CAUSE IS STARTER RELAY CONTROL CIRCUIT OR OTHER

• Crank the engine.

• Is a clicking sound heard from the starter relay?

|

Yes

|

Go to Step 22.

|

|

No

|

Go to the next step.

|

|

14

|

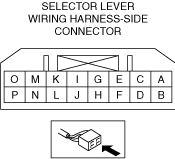

VERIFY SELECTOR LEVER DTCs

• Perform the DTC inspection for the selector lever.

• Are any DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

15

|

INSPECT SELECTOR LEVER CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

16

|

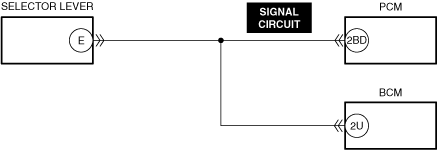

INSPECT SELECTOR LEVER SIGNAL CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

17

|

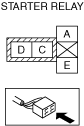

INSPECT STARTER RELAY FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

18

|

INSPECT BODY CONTROL MODULE (BCM) CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

19

|

INSPECT PCM CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

20

|

INSPECT STARTER RELAY CONTROL CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

21

|

INSPECT STARTER RELAY CONTROL CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for open circuit.

• Is the circuit normal?

|

Yes

|

Inspect the body control module (BCM).

• If there is any malfunction:

-

― Replace the body control module (BCM) and perform the repair completion verification.

• If there is no malfunction:

-

― Replace the selector lever and perform the repair completion verification.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

22

|

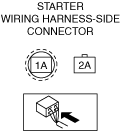

INSPECT STARTER CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

23

|

DETERMINE IF MALFUNCTION CAUSE IS STARTER OR OTHER

• Verify that the starter connector is disconnected.

• Crank the engine.

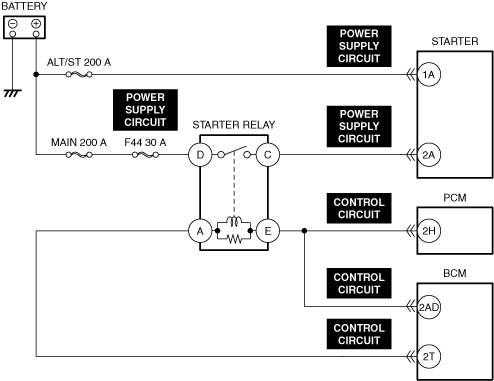

• Measure the voltage at the starter terminal 2A (wiring harness-side)

• Is the voltage B+?

|

Yes

|

Go to Step 27.

|

|

No

|

Go to the next step.

|

|

24

|

INSPECT STARTER RELAY POWER SUPPLY CIRCUIT FOR SHORT TO GROUND AND OPEN CIRCUIT

• Inspect the power supply circuit for an open circuit and short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

25

|

INSPECT POWER SUPPLY CIRCUIT BETWEEN STARTER RELAY AND STARTER FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

26

|

INSPECT POWER SUPPLY CIRCUIT BETWEEN STARTER RELAY AND STARTER FOR OPEN CIRCUIT

• Inspect the applicable circuit for open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

27

|

INSPECT POWER SUPPLY CIRCUIT BETWEEN BATTERY AND STARTER FOR SHORT TO GROUND AND OPEN CIRCUIT

• Inspect the power supply circuit for an open circuit and short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

28

|

INSPECT STARTER FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

29

|

INSPECT IMMOBILIZER SYSTEM RELATED CIRCUIT

• Inspect the following wiring harness and connectors:

-

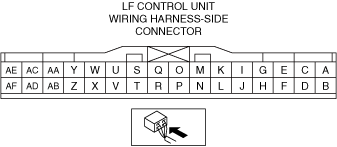

― Between push button start terminal B and LF control unit terminal AF

― Between push button start terminal A and LF control unit terminal AE

― LF control unit terminal M and body control module (BCM) terminal 2L

― LF control unit terminal P and Body control module (BCM) terminal 2J

― Between body control module (BCM) terminal 3X and PCM terminal 2S

― Between body control module (BCM) terminal 3W and PCM terminal 2T

• Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

No

|

Go to the next step.

|

|

30

|

VERIFY PRESENT MALFUNCTION DTC

• Perform the KOEO self test.

• Are any DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

31

|

DETERMINE IF MALFUNCTION CAUSE IS BASE ENGINE OR OTHER

• Inspect for a seized drive plate.

• Is the drive plate seized?

|

Yes

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

No

|

Base engine malfunction or engine damage during compression due to liquid (such as water, fuel, or engine oil) penetration into cylinder.

• Overhaul or replace the engine and perform the repair completion verification.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Has the malfunction symptom been eliminated?

|

Yes

|

Complete the symptom troubleshooting. (Explain contents of repair to customer)

|

|

No

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

• If the CAN communication is normal, perform the diagnosis from Step 1.

-

― If the malfunction recurs, go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF MALFUNCTION IS CAUSED BY NOT PERFORMING PCM REPROGRAMMING

• Verify repair information and verify that there is a new calibration in the PCM.

• Is there a new calibration in the PCM?

|

Yes

|

Perform the PCM reprogramming and verify if the malfunction symptom was corrected.

• If the malfunction recurs, replace the PCM.

|

|

No

|

Replace the PCM.

|