|

TIMING CHAIN REMOVAL/INSTALLATION [MZR 2.0 DISI i-stop]

id011037801000

1. Remove the battery cover. (See BATTERY REMOVAL/INSTALLATION [MZR 2.0 DISI i-stop].)

2. Disconnect the negative battery cable.

3. Remove the plug hole plate. (See PLUG HOLE PLATE REMOVAL/INSTALLATION [MZR 2.0 DISI i-stop].)

4. Disconnect the wiring harness.

5. Remove the high pressure fuel pump. (See HIGH PRESSURE FUEL PUMP REMOVAL/INSTALLATION [MZR 2.0 DISI i-stop].)

6. Remove the ignition coils. (See IGNITION COIL REMOVAL/INSTALLATION [MZR 2.0 DISI i-stop].)

7. Remove the spark plugs. (See SPARK PLUG REMOVAL/INSTALLATION [MZR 2.0 DISI i-stop].)

8. Remove the ventilation hose.

9. Remove the coolant reserve tank with the hose still connected and set it out of the way. (See COOLANT RESERVE TANK REMOVAL/INSTALLATION [MZR 2.0 DISI i-stop].)

10. Remove the front wheel and tire. (RH) (See GENERAL PROCEDURES (SUSPENSION).)

11. Remove the aerodynamic under cover No.2 and splash shield as a single unit. (See AERODYNAMIC UNDER COVER NO.2 REMOVAL/INSTALLATION.) (See SPLASH SHIELD REMOVAL/INSTALLATION.)

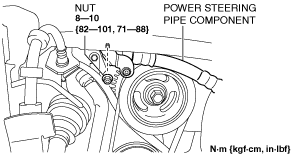

12. Remove the nut shown in the figure and set the power steering pipe component out of the way.

am3zzw00015389

|

13. Remove the crankshaft position (CKP) sensor. (See CRANKSHAFT POSITION (CKP) SENSOR REMOVAL/INSTALLATION [MZR 2.0 DISI i-stop].)

14. Remove the drive belt. (See DRIVE BELT REMOVAL/INSTALLATION [MZR 2.0 DISI i-stop].)

15. Disconnect the drive shaft (RH) from joint shaft, set the drive shaft (RH) out of the way. (MTX) (See DRIVE SHAFT REMOVAL/INSTALLATION.)

16. Remove the A/C compressor with the cooler hose still connected and secure it using wire or rope so that it is out of the way. (See A/C COMPRESSOR REMOVAL/INSTALLATION.)

17. Remove in the order indicated in the table.

18. Install in the reverse order of removal.

19. Start the engine. And inspect and adjust the following:

am3zzw00021078

|

|

1

|

Dipstick

|

|

2

|

Cylinder head cover

|

|

3

|

Crankshaft pulley lock bolt

|

|

4

|

Crankshaft pulley

|

|

5

|

Water pump pulley

|

|

6

|

Drive belt auto tensioner

|

|

7

|

No.3 engine mount

|

|

8

|

Front oil seal

|

|

9

|

Engine front cover

|

|

10

|

Chain tensioner

(See Chain Tensioner Removal Note.)

|

|

11

|

Tensioner arm

|

|

12

|

Chain guide

|

|

13

|

Timing chain

|

|

14

|

Oil pump chain tensioner

|

|

15

|

Oil pump driven sprocket

|

|

16

|

Oil pump chain

|

|

17

|

Crankshaft sprocket

|

|

18

|

Oil pump drive sprocket

|

Cylinder Head Cover Removal Note

1. Loosen the cylinder head cover bolts in the order shown in the figure.

am3zzw00015391

|

Crankshaft Pulley Lock Bolt Removal Note

1. Rotate the crankshaft in the direction of the engine rotation and remove the cylinder block lower blind plug when the No. 1 cylinder is at the point prior to top dead center (TDC) of compression, then install the SST.

am3zzw00015392

|

2. Rotate the crankshaft in the direction of the engine rotation so that the No.1 piston is at TDC of the compression stroke. (Until the counterweight contacts SST and stops.)

3. Hold the crankshaft pulley by using the SSTs.

am3zzw00015393

|

No.3 Engine Mount Removal Note

Oil pan is removed

1. Install the SST using the following procedures.

am3zzw00015394

|

am3zzw00015395

|

am3zzw00015396

|

am3zzw00015397

|

am3zzw00015398

|

Oil pan is not removed

1. Support the engine (oil pan) using a commercially available engine lifter.

am3zzw00015399

|

Chain Tensioner Removal Note

1. Press the timing chain tensioner ratchet to the left using a thin flathead screwdriver (precision screwdriver) to unlock the plunger.

am3zzw00015400

|

2. Slowly press the plunger back in the direction shown in the figure while pressing the ratchet.

am3zzw00015401

|

3. Release the ratchet with the plunger still pressed down.

am3zzw00015402

|

4. Press-in the plunger until the ratchet position is as indicated in the figure, and then insert the wire to lock the plunger.

am3zzw00015403

|

Oil Pump Driven Sprocket Removal Note

1. Temporarily install the crankshaft pulley and crankshaft pulley lock bolt to the crankshaft, and lock the oil pump against rotation as shown in figure.

am3zzw00015404

|

2. Remove the oil pump driven sprocket, and then remove the crankshaft pulley and crankshaft pulley lock bolt.

Oil Pump Drive Sprocket Installation Note

1. The oil pump drive sprocket has the assembly direction as shown in the figure.

am3zzw00015405

|

Oil Pump Driven Sprocket Installation Note

1. Temporarily install the crankshaft pulley and crankshaft pulley lock bolt to the crankshaft, and lock the oil pump against rotation as shown in figure.

am3zzw00015406

|

2. Install the oil pump driven sprocket, and then remove the crankshaft pulley and crankshaft pulley lock bolt.

Timing Chain Installation Note

1. Install the SST to the camshaft as shown in the figure.

am3zzw00015407

|

2. Install the timing chain.

3. Remove the wire or paper clip from the chain tensioner piston and apply tension to the timing chain.

Engine Front Cover Installation Note

1. Apply silicone sealant to the engine front cover as shown.

am3zzw00015408

|

2. Tighten the engine front cover installation bolts in the order shown in the figure.

am3zzw00015409

|

|

No. |

Tightening torque |

|---|---|

|

1―18

|

8—11 N·m {82—112 kgf·cm, 71—97 in·lbf}

|

|

19―22

|

40—55 N·m {4.1—5.6 kgf·m, 30—40 ft·lbf}

|

|

23

|

20—30 N·m {2.1—3.0 kgf·m, 15—22 ft·lbf}

|

No.3 Engine Mount Installation Note

1. Tighten the No.3 engine mount stud bolts.

am3zzw00015410

|

2. Temporarily tighten the No.3 engine mount installation bolts and nuts.

3. Tighten the No.3 engine mount installation bolts and nuts in the order shown in the figure.

am3zzw00015411

|

Crankshaft Pulley Lock Bolt Installation Note

1. Install the SST to the camshaft as shown in the figure.

am3zzw00015407

|

2. Verify that the No.1 cylinder is at TDC of the compression stroke. (The position counterweight contacts the SST.)

3. To position the crankshaft pulley, temporarily tighten it and, using a suitable bolt (M6 X 1.0 length 25—35 mm {1.0—1.3 in}), fix the crankshaft pulley to the engine front cover.

am3zzw00015412

|

4. Install the SSTs to the crankshaft pulley, lock the crankshaft against rotation, and tighten the crankshaft pulley lock bolt using the following two steps using the SST (49 D032 316).

am3zzw00015413

|

5. Remove the bolt (M6 X 1.0 length 25—35 mm {1.0—1.3 in}) installed to the crankshaft pulley.

6. Remove the SST from the camshaft.

7. Remove the SST installed in the cylinder block lower blind plug hole.

8. Rotate the crankshaft clockwise two turns and inspect the valve timing.

9. Install the cylinder block lower blind plug.

am3zzw00015414

|

Cylinder Head Cover Installation Note

1. Apply silicone sealant to the areas shown in the figure.

am3zzw00015415

|

am3zzw00015416

|

2. Tighten the cylinder head cover bolts in the order shown in the figure.

am3zzw00015417

|