DTC P0841:00

Oil pressure switch circuit malfunction

DETECTION CONDITION

• When DTC P0731:00, P0732:00, P0733:00 and P0734:00 are not output and 10 s or more has passed.

-

― When all the conditions below are satisfied while driving in 1GR, 2GR or 3GR

-

• ATF temperature 20 °C {68 °F} or more• Oil pressure switch OFF• Revolution ratio of forward clutch drum revolution to differential gear case revolution within 0.91—3.07• None of the following DTCs are present: P0706:00, P0707:00, P0708:00, P0712:00, P0713:00, P0715:00, P0720:00, P0751:00, P0752:00, P0753:00, P0756:00, P0757:00, P0758:00, P0761:00, P0762:00, P0763:00, P0766:00, P0767:00, P0768:00, P0771:00, P0772:00, P0773:00, P0791:00

-

-

― When all conditions below are satisfied while driving in 4GR or 5GR

-

• ATF temperature 20 °C {68 °F} or more• Oil pressure switch ON• Revolution ratio of forward clutch drum revolution to differential gear case revolution within 0.64—0.81• None of the following DTCs are present: P0706:00, P0707:00, P0708:00, P0712:00, P0713:00, P0715:00, P0720:00, P0751:00, P0752:00, P0753:00, P0756:00, P0757:00, P0758:00, P0761:00, P0762:00, P0763:00, P0766:00, P0767:00, P0768:00, P0771:00, P0772:00, P0773:00, P0791:00

-

Diagnostic support note:

• This is a continuous monitor (CCM).

• The MIL does not illuminate.

• A PENDING CODE is not available.

• FREEZE FRAME DATA is not available.

• The AT warning light does not illuminate.

• The DTC is stored in the TCM memory.

POSSIBLE CAUSE

• ATF level low

• Deteriorated ATF

• Line pressure low

• Oil pressure switch malfunction

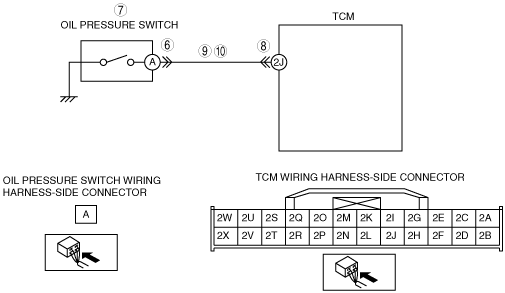

• Open circuit in wiring harness between oil pressure switch terminal A and TCM terminal 2J

• Short to ground in wiring harness between oil pressure switch terminal A and TCM terminal 2J

• Damaged connector between oil pressure switch and TCM

• Control valve stuck

• TCM malfunction