|

1

|

RECORD VEHICLE STATUS WHEN DTC WAS DETECTED TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the snapshot data.

-

Note

-

• Recording can be facilitated using the screen capture function of the PC.

|

—

|

Go to the next step.

|

|

2

|

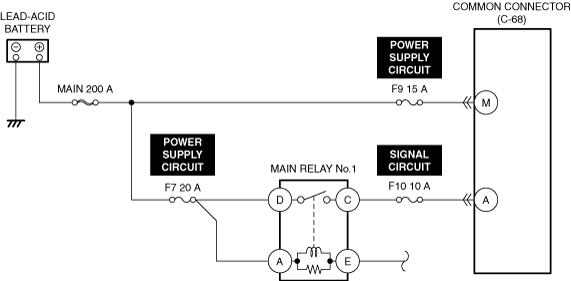

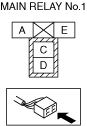

INSPECT MAIN RELAY No.1 FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

3

|

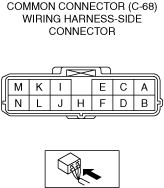

INSPECT MAIN RELAY No.1 POWER SUPPLY CIRCUIT FOR SHORT TO GROUND AND OPEN CIRCUIT

• Verify that the service plug is removed.

• Inspect the power supply circuit for an open circuit and short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

4

|

INSPECT F10 10 A FUSE

• Verify that the service plug is removed.

• Remove the F10 10 A fuse.

• Inspect the F10 10 A fuse.

• Is the fuse normal?

|

Yes

|

Reinstall the F10 10 A fuse, then go to the next step.

|

|

No

|

Replace the F10 10 A fuse and perform the repair completion verification 1.

|

|

5

|

INSPECT LEAD-ACID BATTERY FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Recharge or replace the lead-acid battery and perform the repair completion verification 1.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Access the BECM simulation item [HV_BATT_EEV_COMD] using the M-MDS.

• Changes the opening angle of the battery cooling refrigerant valve.

• Perform the DTC inspection for the BECM.

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the high voltage battery, then go to the next step.

|

|

No

|

Go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF OTHER DTCs DISPLAYED

• Perform the DTC inspection.

• Are any other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|