|

1

|

Do any of the following conditions appear?

• Engine does not start completely.

• PCM DTC P1260:00 is displayed.

|

Yes

|

Both conditions are appear:

• Go to Step 5.

|

|

No

|

Either or other condition appears:

• Go to the next step.

|

|

2

|

Does the engine stall after approx. 2 s from when it is started?

|

Yes

|

Go to the next step.

|

|

No

|

Immobilizer system is normal.

• Go to Step 12.

|

|

3

|

Inspect the connection of coil antenna connector.

Is the coil antenna connector securely connected to the coil antenna?

|

Yes

|

Go to the next step.

|

|

No

|

Reconnect the coil antenna securely, then repeat from Step 2.

|

|

4

|

Does the security light illuminate?

|

Yes

|

Go to the next step.

|

|

No

|

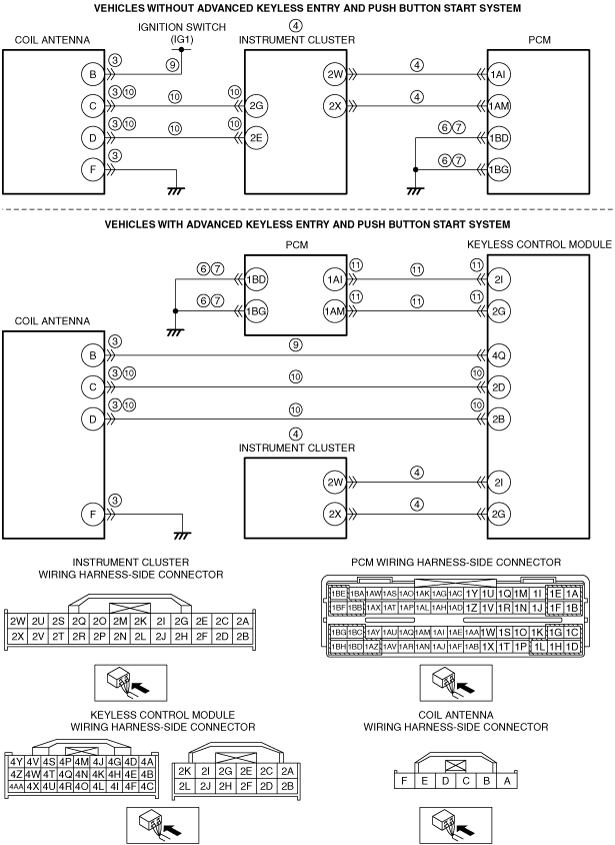

Inspect the following wiring harness:

• Vehicles without advanced keyless entry and push button start system:

-

― Between PCM terminal 1AI and instrument cluster terminal 2W

― Between PCM terminal 1AM and instrument cluster terminal 2X

• Vehicles with advanced keyless entry and push button start system:

-

― Between keyless control module terminal 2I and instrument cluster terminal 2W

― Between keyless control module terminal 2G and instrument cluster terminal 2X

Repair or replace the malfunctioning part according to the inspection results.

|

|

5

|

Retrieve the immobilizer system DTC using the M-MDS.

Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

Go to the next step.

|

|

6

|

Switch the ignition to off.

Inspect for continuity between PCM terminals 1AZ, 1BB, 1BD, 1BG, 1BH (wiring harness-side) and body ground.

Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the suspected wiring harness.

|

|

7

|

Switch the ignition to ON (engine off).

Measure the voltage at the PCM terminal 1AZ, 1BB, 1BD, 1BG and 1BH (wiring harness-side).

Is the voltage below 1.0 V?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the suspected wiring harness.

|

|

8

|

Access the VPWR PID using the M-MDS.

Is the VPWR PID value normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning part according to the inspection results.

|

|

9

|

Switch the ignition to off.

Disconnect the coil antenna connector.

Switch the ignition to ON (engine off).

Measure the voltage at the coil antenna terminal B (wiring harness-side).

Is the voltage B+?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the suspected wiring harness.

|

|

10

|

Inspect the following wiring harness and connectors:

• Vehicles without advanced keyless entry and push button start system:

-

― Between coil antenna terminal C and instrument cluster terminal 2G

― Between coil antenna terminal D and instrument cluster terminal 2E

• Vehicles with advanced keyless entry and push button start system:

-

― Between coil antenna terminal C and keyless control module terminal 2D

― Between coil antenna terminal D and keyless control module terminal 2B

Is there any malfunction (open or short circuit, terminal corrosion, etc.)?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results.

|

|

No

|

Vehicles without advanced keyless entry and push button start system:

• Go to Step 12.

Vehicles with advanced keyless entry and push button start system:

• Go to the next step.

|

|

11

|

Inspect the following wiring harness and connectors:

• Between PCM terminal 1AI and keyless control module terminal 2I

• Between PCM terminal 1AM and keyless control module terminal 2G

Is there any malfunction (open or short circuit, terminal corrosion, etc.)?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results.

|

|

No

|

Go to the next step.

|

|

12

|

Inspect for following:

• Fuel quality (proper octane, contamination, winter/summer blend)

• Intake-air system leakage and restriction

• Electrical connectors

• Poor connection for PCM ground and body ground

• Fuel leakage

• Vacuum leakage

Is there any malfunction?

|

Yes

|

Service if necessary.

• Repeat this step.

|

|

No

|

Go to the next step.

|

|

13

|

Retrieve any PCM DTCs using the M-MDS.

Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

Go to the next step.

|

|

14

|

Access the ECT PID using the M-MDS.

Is the ECT PID value less than 116 °C {241 °F} during driving?

|

Yes

|

Go to the next step.

|

|

No

|

The cause of this concern could be from the cooling system overheating.

• Perform the symptom troubleshooting “NO.17 COOLING SYSTEM CONCERNS-OVERHEATING”.

|

|

15

|

Access the VPWR PID using the M-MDS.

Is the VPWR PID value B+?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness between main relay terminal C and PCM terminal 1BE and 1BF.

|

|

16

|

Perform the A/C Cut-off Control System Inspection.

Does the A/C cut-off operation work properly?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning part according to the inspection results.

|

|

17

|

Will the engine run smoothly at part throttle?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 19.

|

|

18

|

Perform the TP sweep inspection.

Does the electronic throttle control system work properly?

|

Yes

|

Visually inspect the throttle body (damage/scratching).

• If there is any malfunction:

-

― Repair or replace the malfunctioning part according to the inspection results.

• If there is no malfunction:

-

― Go to the next step.

|

|

No

|

Repair or replace the malfunctioning part according to the inspection results.

|

|

19

|

Perform the EGR Control System Inspection.

Does the EGR system operate properly?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning part according to the inspection results.

|

|

20

|

Perform the Purge Control System Inspection.

Does the purge solenoid valve work properly?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning part according to the inspection results.

|

|

21

|

Perform the Variable Valve Timing Control System Operation Inspection.

Does the variable valve timing control system work properly?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning part according to the inspection results.

|

|

22

|

Inspect the CMP sensor and CKP sensor for the following:

• Damaged trigger wheel and camshaft

• Open or short circuit in related circuit

Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results.

|

|

No

|

Go to the next step.

|

|

23

|

-

Caution

-

• While performing this step, always operate the vehicle in a safe and lawful manner.

• When the M-MDS is used to observe monitor system status while driving, be sure to have another technician with you, or record the data in the M-MDS using the PID/DATA MONITOR AND RECORD capturing function and inspect later.

Access the following PIDs using the M-MDS:

• APP

• ECT

• LONGFT1

• MAF

• O2S11

• O2S12

• SHTFT1

Do the PIDs indicate the correct values under the trouble condition?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning part according to the inspection results.

• If the malfunction remains:

-

― Perform the “INTERMITTENT CONCERN TROUBLESHOOTING” procedure.

|

|

24

|

Inspect for restriction in the exhaust system and the TWC.

Is there any restriction?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results.

|

|

No

|

Go to the next step.

|

|

25

|

Perform the Spark Test.

Is a strong blue spark visible at each cylinder?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning part according to the inspection results.

|

|

26

|

Access the FUEL_PRES PID using the M-MDS.

Is the FUEL_PRES PID value within the specification?

|

Yes

|

Go to Step 31.

|

|

No

|

Go to the next step.

|

|

27

|

Is the vehicle accelerate performance normally?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 29.

|

|

28

|

Inspect the fuel pressure sensor.

Is there any malfunction?

|

Yes

|

Replace the fuel delivery pipe.

|

|

No

|

Go to Step 31.

|

|

29

|

Switch the ignition to off.

Disconnect the high pressure fuel pump and PCM connectors.

Inspect for continuity between high pressure fuel pump terminal A (wiring harness-side) and body ground.

Is there continuity?

|

Yes

|

Repair or replace the wiring harness for a possible short to ground.

• If the malfunction remains:

-

― Replace the PCM. (damage to driver in PCM)

|

|

No

|

Go to the next step.

|

|

30

|

Replace the high pressure fuel pump.

Access the FUEL_PRES PID using the M-MDS.

Is the FUEL_PRES PID value within the specification?

|

Yes

|

High pressure fuel pump or spill valve control solenoid valve (built-in high pressure fuel pump) malfunction.

• Symptom troubleshooting is completed.

• Go to Step 35.

|

|

No

|

Relief valve (built-in fuel delivery pipe) malfunction.

• Replace the fuel delivery pipe.

|

|

31

|

Connect the fuel pressure gauge between fuel pump and high pressure fuel pump.

Measure the low side fuel pressure.

Is the low side fuel pressure within the specification?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect for following:

• Fuel line restriction

• Fuel filter clogging

-

― If there is any malfunction:

-

• Repair or replace the malfunctioning part according to the inspection results.

― If there is no malfunction:

-

• Replace the fuel pump unit.

|

|

32

|

Perform the Fuel Injector Operation Inspection.

Do the fuel injectors operate properly?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning part according to the inspection results.

|

|

33

|

Measure the compression pressure for each cylinder.

Are the compression pressures within the specification?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect for following:

• Damaged valve seat

• Worn valve stem and valve guide

• Worn or stuck piston ring

• Worn piston, piston ring or cylinder

• Improper valve timing

Service if necessary.

|

|

34

|

Inspect the PCV valve.

Is there any malfunction?

|

Yes

|

Replace the PCV valve.

|

|

No

|

Injector driver is malfunction.

If the malfunction remains:

• Overhaul the engine.

|

|

35

|

Verify the test results.

• If a malfunction remains, inspect the related Service Information and perform the repair or diagnosis.

-

― If the vehicle is repaired, troubleshooting is completed.

|