Malfunction symptom

EV system does not start

Description

• The EV system does not start even though the power switch is operated.

• The power switch POWER indicator light does not turn on even when the main power is switched ON.

• READY is not displayed in the instrument cluster after the EV system starts.

Possible cause

EV system start conditions are not met:

• Power switch signal circuit malfunction (body control module (BCM) detects DTC)

-

― Short to power supply in power switch signal circuit― Open circuit in power switch signal circuit

• Power switch malfunction

• The body control module (BCM) recognizes that the brake pedal is not depressed.

-

― Brake switch malfunction― Malfunction in wiring harness between brake switch and body control module (BCM), or connectors

• Body control module (BCM) recognizes that steering lock is not released

-

― Steering lock unit malfunction

• PCM and body control module (BCM) recognizes position other than P position

-

― CAN communication error― Parking lock actuator malfunction― Selector lever malfunction

• Body control module (BCM) malfunction

• PCM cannot receive start request from body control module (BCM)

-

― CAN communication error

• Fail-safe due to PCM, drive motor control module or BECM DTC detection

-

― EV system malfunction― High voltage battery voltage decreased

• False recognition that charge connector is connected

-

― Normal charge port connection detection circuit malfunction (battery charge control module detects DTC)― Quick charge port connection detection circuit (PCM detects DTC)

• High voltage battery charging (normal operation)

-

Note

-

• If the high voltage contactor does not activate, DTC P0AE3:00 is detected.

High voltage contactor cannot be driven:

• Discharged lead-acid battery (See DISCHARGED LEAD-ACID BATTERY.)

• Short circuit in power transistor of PTC internal high voltage circuit

Power switch POWER indicator light false illumination:

• Power switch POWER indicator light control circuit malfunction

-

― Short to power supply in power switch POWER indicator light control circuit

• Body control module (BCM) malfunction

READY status incorrect display

• Instrument cluster cannot receive main power status signal

-

― CAN communication malfunction

• Instrument cluster malfunction

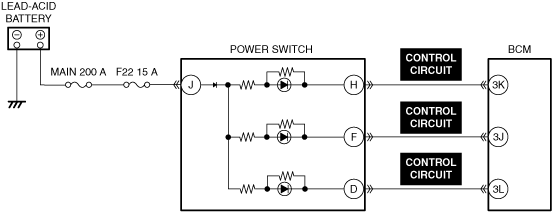

System wiring diagram

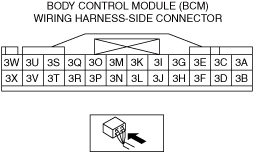

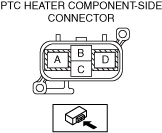

Connector diagram