|

ENGINE REMOVAL/INSTALLATION [MZI-3.7]

id0110c5800400

1. Perform “Fuel Line Safety Procedures”. Leave the fuel pump relay removed. (See BEFORE SERVICE PRECAUTION [MZI-3.7].)

2. Disconnect both battery cables.

3. Remove the battery and battery tray. (See BATTERY REMOVAL/INSTALLATION [MZI-3.7].)

4. Drain the power steering fluid. (See POWER STEERING FLUID INSPECTION.)

5. Drain the engine coolant. (See ENGINE COOLANT REPLACEMENT [MZI-3.7].)

6. Remove the engine cover. (See ENGINE COVER REMOVAL/INSTALLATION [MZI-3.7].)

7. Remove the ventilation hose. (See QUICK RELEASE CONNECTOR (EMISSION SYSTEM) REMOVAL/INSTALLATION [MZI-3.7].)

8. Disconnect the vacuum hose. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [MZI-3.7].)

9. Remove the air cleaner. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [MZI-3.7].)

10. Remove the resonance chamber. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [MZI-3.7].)

11. Remove the both front wheels and tires. (See GENERAL PROCEDURES (SUSPENSION).)

12. Remove the splash shield (RH).

13. Remove the generator and A/C drive belt. (See DRIVE BELT REMOVAL/INSTALLATION [MZI-3.7].)

14. Disconnect the front drive shaft (RH) from the joint shaft side. (See FRONT DRIVE SHAFT REMOVAL/INSTALLATION.)

15. Disconnect the front drive shaft (LH) from the transaxle side. (See FRONT DRIVE SHAFT REMOVAL/INSTALLATION.)

16. Remove the front pipe and middle pipe as a single unit. (See EXHAUST SYSTEM REMOVAL/INSTALLATION [MZI-3.7].)

17. Position the propeller shaft out of the way. (See PROPELLER SHAFT REMOVAL/INSTALLATION.)

18. Disconnect the selector cable from the transaxle side. (See AUTOMATIC TRANSAXLE REMOVAL/INSTALLATION [AW6AX-EL].)

19. Disconnect the heater hose. (See HEATER PIPE AND HOSE COMPONENT REMOVAL/INSTALLATION.)

20. Remove the engine hanger installation bolt, and power steering oil pump hose out of the way (R.H.D.). (See POWER STEERING OIL PUMP REMOVAL/INSTALLATION [R.H.D.].)

21. Disconnect the power steering return hose. (See POWER STEERING OIL PUMP REMOVAL/INSTALLATION [L.H.D.].) (See POWER STEERING OIL PUMP REMOVAL/INSTALLATION [R.H.D.].)

22. Disconnect the radiator hose. (See RADIATOR REMOVAL/INSTALLATION [MZI-3.7].)

23. Disconnect the water hose. (See OIL COOLER REMOVAL/INSTALLATION [MZI-3.7].)

24. Disconnect the ATF oil cooler hose.

25. Disconnect the plastic fuel hose. (See BEFORE SERVICE PRECAUTION [MZI-3.7].) (See QUICK RELEASE CONNECTOR (EMISSION SYSTEM) REMOVAL/INSTALLATION [MZI-3.7].)

26. Disconnect the wiring harness.

27. Remove the A/C compressor with the pipes connected and secure the A/C compressor using wire or rope so that it is out of the way. (See A/C COMPRESSOR REMOVAL/INSTALLATION.)

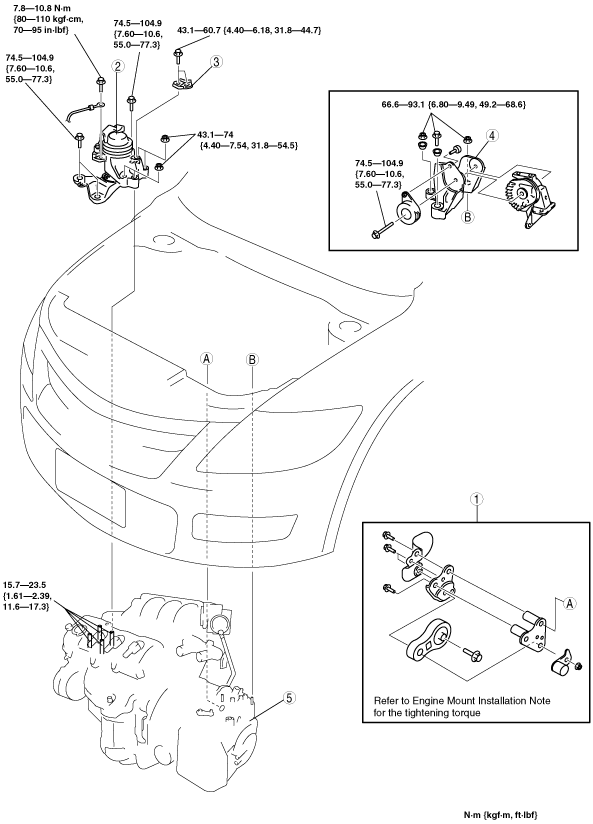

28. Remove the engine and transaxle component using an engine jack in the order indicated in the figure.

29. Install in the reverse order of removal.

30. Start the engine and:

31. Perform a road test.

ac9wzw00001545

|

|

1

|

No.1 engine mount

|

|

2

|

No.3 engine mount rubber

|

|

3

|

No.3 engine mount stay (No.3 engine mount side)

|

|

4

|

No.4 engine mount bracket

|

|

5

|

Engine and transaxle

|

No.1 Engine Mount Removal Note

1. Remove the front under cover A and front under cover B. (See FRONT UNDER COVER REMOVAL/INSTALLATION.)

2. Remove the transverse member. (See TRANSVERSE MEMBER REMOVAL/INSTALLATION.)

3. Remove the intermediate shaft installation bolt, and disconnect the steering shaft. (See STEERING WHEEL AND COLUMN REMOVAL/INSTALLATION.)

4. Remove the No.1 engine mounting bracket bolts.

ac9wzw00000697

|

5. Remove the No.1 engine mount, No.1 engine mount bracket and the front crossmember as a single unit. (See FRONT CROSSMEMBER REMOVAL/INSTALLATION [L.H.D.].) (See FRONT CROSSMEMBER REMOVAL/INSTALLATION [R.H.D.].)

ac9wzw00000784

|

No.3 Engine Mount Rubber and No.4 Engine Mount Bracket Removal Note

1. Secure the engine and transaxle using an engine jack and attachment.

acxuuw00000188

|

2. Secure the engine, transaxle, and crossmember component using a hoist.

Engine and Transaxle Removal Note

ac9uuw00000223

|

Engine Mount Installation Note

1. Tighten the No.3 engine mount stud bolts.

ac9wzw00000785

|

2. Secure the engine and the transaxle using an engine jack and attachment as shown.

ac9uuw00000220

|

3. Temporarily tighten the No.3 engine mount bolt and nuts in the order shown in the figure.

ac9uuw00000222

|

4. Temporarily tighten the No. 4 engine mount bracket in two passes.

ac9uuw00000890

|

ac9uuw00000233

|

5. Install the No.1 engine mount, No.1 engine mount bracket and the front crossmember as a single unit. (See FRONT CROSSMEMBER REMOVAL/INSTALLATION [L.H.D.].) (See FRONT CROSSMEMBER REMOVAL/INSTALLATION [R.H.D.].)

ac9wzw00000784

|

6. Tighten the No.1 engine mount bracket bolt A and B in order of A→B.

ac9wzw00000787

|

7. Tighten the No.1 engine mount bolt C at the specified torque.

ac9uuw00003036

|

8. Install the intermediate shaft installation bolt, and disconnect the steering shaft. (See STEERING WHEEL AND COLUMN REMOVAL/INSTALLATION.)

9. Install the transverse member. (See TRANSVERSE MEMBER REMOVAL/INSTALLATION.)

10. Install the front under cover A and front under cover B. (See FRONT UNDER COVER REMOVAL/INSTALLATION.)

11. Tighten the No.3 engine mount in the order shown in the figure.

ac9uuw00000222

|

Tightening Torque

|

Installation Position |

Tightening Torque |

|---|---|

|

1, 2, 7

|

74.5—104.9 N·m {7.60—10.6 kgf·m, 55.0—77.3 ft·lbf}

|

|

3, 4, 5, 6

|

43.1—74 N·m {4.40—7.54 kgf·m, 31.8—54.5 ft·lbf}

|

12. Tighten the No.3 engine mount stay (No.3 engine mount side).

13. Tighten the No.4 engine mount in the order shown in the figure.

ac9uuw00000231

|

Tightening Torque

|

Installation Position |

Tightening Torque |

|---|---|

|

1, 2, 3

|

66.6—93.1 N·m {6.80—9.49 kgf·m, 49.2—68.6 ft·lbf}

|

|

4

|

74.5—104.9 N·m {7.60—10.6 kgf·m, 55.0—77.3 ft·lbf}

|