|

1

|

INSPECT VEHICLE CONTROL MODULE (VCM) AND BODY CONTROL MODULE (BCM) FOR MALFUNCTION

• Switch the main power OFF, and then switch it ON (READY off).

• Perform the DTC inspection for the vehicle control module (VCM) and the body control module (BCM).

• Is a DTC related to an internal malfunction displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

2

|

INSPECT DRIVER MONITORING CAMERA UNIT FOR MALFUNCTION

• Perform the DTC inspection for the driver monitoring camera unit.

• Is a DTC displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

3

|

VERIFY DTCs

• Perform the DTC inspection for the following modules.

-

― PCM

― DC-DC converter

• Are any DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

4

|

INSPECT LEAD-ACID BATTERY FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

5

|

INSPECT VEHICLE CONTROL MODULE (VCM) CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

6

|

INSPECT VEHICLE CONTROL MODULE (VCM) POWER SUPPLY CIRCUIT FOR SHORT TO GROUND AND OPEN CIRCUIT

• Inspect the power supply circuit for a short to ground and open circuit.

• Is the circuit normal?

|

Yes

|

-

Note

-

• If the diagnostic procedure in Step 7 through Step 18 has been completed, go to Step 19.

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

7

|

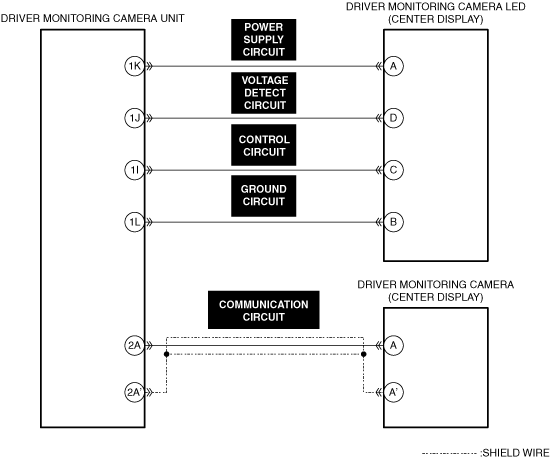

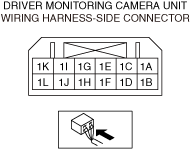

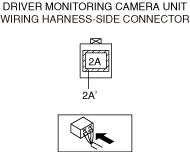

INSPECT DRIVER MONITORING CAMERA UNIT CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

8

|

INSPECT VEHICLE CONTROL MODULE (VCM) CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

9

|

INSPECT DRIVER MONITORING CAMERA UNIT GROUND CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

10

|

INSPECT DRIVER MONITORING CAMERA UNIT POWER SUPPLY CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

11

|

INSPECT DRIVER MONITORING CAMERA UNIT POWER SUPPLY CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

12

|

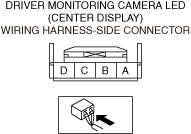

INSPECT DRIVER MONITORING CAMERA LED CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

13

|

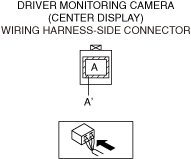

INSPECT DRIVER MONITORING CAMERA CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

14

|

INSPECT DRIVER MONITORING CAMERA COMMUNICATION CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

15

|

INSPECT DRIVER MONITORING CAMERA COMMUNICATION CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

16

|

INSPECT DRIVER MONITORING CAMERA LED POWER SUPPLY CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

17

|

INSPECT DRIVER MONITORING CAMERA LED POWER SUPPLY CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

18

|

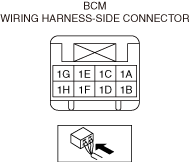

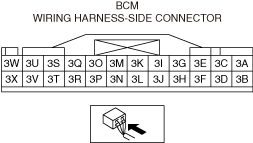

INSPECT VEHICLE CONTROL MODULE (VCM) POWER SUPPLY VOLTAGE

• Reconnect all the disconnected connectors.

• Connect the negative lead-acid battery terminal.

• Measure the voltage at body control module (BCM) terminal 3G.

|

Yes

|

-

Note

-

• If the diagnostic procedure in Step 4 through Step 6 has not been completed, go to Step 4.

Go to the next step.

|

|

No

|

Replace the body control module (BCM) and perform the repair completion verification.

|

|

19

|

INSPECT DRIVER MONITORING CAMERA UNIT FOR MALFUNCTION DEPENDING ON REPEATABILITY

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Switch the main power ON (READY off or on) and wait for 15 s or more.

• Perform the DTC inspection for the vehicle control module (VCM).

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, replace the driver monitoring camera unit and perform the repair completion verification.

|

|

No

|

Go to repair completion verification 2.

|

|

20

|

INSPECT DRIVER MONITORING CAMERA FOR MALFUNCTION DEPENDING ON REPEATABILITY

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Switch the main power ON (READY off or on) and wait for 15 s or more.

• Perform the DTC inspection for the vehicle control module (VCM).

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, replace the center display and perform the repair completion verification.

|

|

No

|

Perform the [Action for Non-repeatable Malfunction].

If DTC is displayed

• Repeat the diagnosis from Step 1.

If DTC is not displayed

• Go to repair completion verification 2.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Switch the main power ON (READY off or on) and wait for 15 s or more.

• Perform the DTC inspection for the vehicle control module (VCM).

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the body control module (BCM), then go to the next step.

|

|

No

|

Go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF OTHER DTCs ARE DISPLAYED

• Perform the DTC inspection.

• Is a DTC displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|