|

ELECTRIC POWER STEERING (EPS) ON-BOARD DIAGNOSIS

id060200813500

On-Board Diagnostic (OBD) Test Description

Read/clear diagnostic results

PID/Data monitor and record

Reading DTCs Procedure

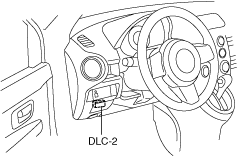

1. Connect the M-MDS (IDS) to the DLC-2.

am2zzw00001261

|

2. After the vehicle is identified, select the following items from the initialization screen of the IDS.

3. Verify the DTC according to the directions on the screen.

4. After completion of repairs, clear all DTCs stored in the EPS CM. (See Clearing DTCs Procedures.)

Clearing DTCs Procedures

1. Connect the M-MDS (IDS) to the DLC-2.

am2zzw00001261

|

2. After the vehicle is identified, select the following items from the initialization screen of the IDS.

3. Verify the DTC according to the directions on the screen.

4. Press the clear button on the DTC screen to clear the DTC.

5. Switch the ignition to off.

6. Switch the ignition to ON and wait for 5 s or more.

7. Perform DTC inspection. (See Reading DTCs Procedure.)

8. Verify that no DTCs are displayed.

PID/Data Monitor and Record Procedure

1. Connect the M-MDS (IDS) to the DLC-2.

am2zzw00001261

|

2. After the vehicle is identified, select the following items from the initialization screen of the IDS.

3. Select the applicable PID from the PID table.

4. Verify the PID data according to the directions on the screen.

DTC Table

|

DTC |

Diagnosis system component |

Page |

|---|---|---|

|

M-MDS |

||

|

C1B00:2F

|

Steering angle sensor

|

|

|

C1B00:54

|

Steering angle sensor

|

(See DTC C1B00:54, C1B00:95.)

|

|

C1B00:61

|

Steering angle sensor

|

|

|

C1B00:62

|

Steering angle sensor

|

|

|

C1B00:95

|

Steering angle sensor (mis-assembly)

|

(See DTC C1B00:54, C1B00:95.)

|

|

C200B:2F

|

Torque sensor

|

|

|

C200B:61

|

Torque sensor

|

|

|

C200C:2F

|

Torque sensor

|

|

|

C200D:49

|

EPS motor

|

|

|

U0001:88

|

CAN system communication error

|

(See DTC U0001:88.)

|

|

U0100:00

|

CAN system communication error

|

(See DTC U0100:00.)

|

|

U0300:00

|

EPS CM

|

(See DTC U0300:00.)

|

|

U0401:00

|

CAN system communication error

|

(See DTC U0401:00.)

|

|

U2011:49

|

EPS motor

|

|

|

U2011:61

|

EPS motor

|

|

|

U2100:00

|

EPS configuration

|

(See DTC U2100:00.)

|

|

U3000:05

|

EPS CM

|

|

|

U3000:41

|

EPS CM

|

|

|

U3000:43

|

EPS CM

|

|

|

U3000:46

|

EPS CM

|

|

|

U3000:49

|

EPS CM

|

|

|

U3000:61

|

EPS CM

|

|

|

U3000:96

|

EPS CM

|

|

|

U3003:16

|

Battery power supply

|

(See DTC U3003:16/U3003:17.)

|

|

U3003:17

|

Battery power supply

|

(See DTC U3003:16/U3003:17.)

|

|

U3004:49

|

EPS CM

|

(See DTC U3004:49.)

|

PID/DATA Monitor Table

|

PID name (definition) |

Unit/Operation |

Operation Status (Reference) |

Inspection item(s) |

EPS control module terminal |

|---|---|---|---|---|

|

M-MDS display |

||||

|

BOARD_T

|

°C, °F

|

• Displays temperature of board in EPS control module: -40°C—+215°C {-40°F—419°F}

|

• Steering column replacement (See STEERING WHEEL AND COLUMN REMOVAL/INSTALLATION [L.H.D.].)

|

—

|

|

DTC_CNT

|

—

|

• When DTC detected: 1—255

• When DTC not detected: 0

|

• DTC inspection (See ELECTRIC POWER STEERING (EPS) ON-BOARD DIAGNOSIS.)

|

—

|

|

ENG_RPM

|

RPM

|

• Engine stopped: 0 RPM

• Engine rotating at 3,000 RPM: 3,000 RPM

|

• PCM inspection (See PCM INSPECTION [MZR 1.3, MZR 1.5].) (See PCM INSPECTION [MZ-CD 1.6].)

|

—

|

|

MTR_CUR

|

A

|

• When not steered: Near 0 A

• Steered: Changes to positive or negative

|

• Steering column replacement (See STEERING WHEEL AND COLUMN REMOVAL/INSTALLATION [L.H.D.].)

|

—

|

|

SS_TRQ1

|

Nm

|

• Not steered: Near 0 Nm

• Steered left: Changes to 0 Nm—Positive

• Steered right: Changes to 0 Nm—Negative

|

• Steering column replacement (See STEERING WHEEL AND COLUMN REMOVAL/INSTALLATION [L.H.D.].)

|

—

|

|

SS_TRQ2

|

Nm

|

• Not steered: Near 0 Nm

• Steered left: Changes to 0 Nm—Positive

• Steered right: Changes to 0 Nm—Negative

|

• Steering column replacement (See STEERING WHEEL AND COLUMN REMOVAL/INSTALLATION [L.H.D.].)

|

—

|

|

STEER_ANGL

|

°

|

• Steering in neutral position

• Steered left: Changes to 0°—Positive

• Steered right: Changes to 0°—Negative

|

• EPS steering angle calibration (See EPS STEERING ANGLE CALIBRATION.)

|

—

|

|

STEER_SPD

|

°/s

|

• Not steered: Near 0 °/s

• Steered: Changes according to steering speed

|

• Steering column replacement (See STEERING WHEEL AND COLUMN REMOVAL/INSTALLATION [L.H.D.].)

|

—

|

|

VPWR

|

V

|

• Engine stopped: Approx. 12 V

• Idling: Approx. 14 V

|

• Battery inspection (See BATTERY INSPECTION [MZR 1.3, MZR 1.5].) (See BATTERY INSPECTION [MZ-CD 1.6].)

• Power supply circuit inspection (ignition switch, fuses)

|

3A

|

|

VSPD

|

KPH, MPH

|

• Vehicle stopped: 0 KPH, 0 MPH

• Vehicle speed 20 km/h {12 mph}: 20 KPH, 12 MPH

|

• PCM inspection (See PCM INSPECTION [MZR 1.3, MZR 1.5].) (See PCM INSPECTION [MZ-CD 1.6].)

• ABS HU/CM inspection (See ABS HU/CM INSPECTION.)

|

—

|