|

1

|

CONFIRM PCM DTC

• Perform the PCM DTC inspection using the M-MDS.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

Go to the next step.

|

|

2

|

INSPECT BATTERY

• Is there any malfunction?

|

Yes

|

Recharge or replace the battery, then go to Step 13.

|

|

No

|

Go to the next step.

|

|

3

|

INSPECT GENERATOR

• Is there any malfunction?

|

Yes

|

Replace the generator, then go to Step 13.

|

|

No

|

Go to the next step.

|

|

4

|

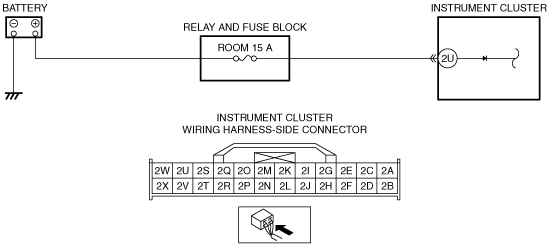

INSPECT INSTRUMENT CLUSTER CONNECTOR AND TERMINALS

• Switch the ignition to off.

• Disconnect the negative battery cable.

• Disconnect the instrument cluster connector.

• Inspect the connector for poor connection (such as damaged/pulled-out pins, and corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector or terminals, then go to Step 13.

|

|

No

|

Go to the next step.

|

|

5

|

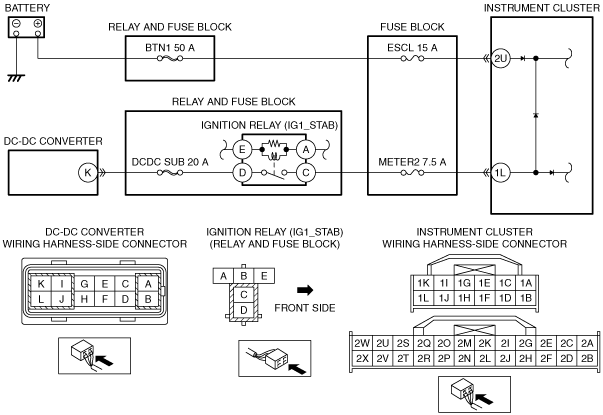

VERIFY MALFUNCTIONING LOCATION

• Verify that the instrument cluster connector is disconnected.

• Reconnect the negative battery cable.

• Switch the ignition to ON.

• Measure the voltage at the following terminals (wiring harness-side):

-

― Instrument cluster terminal 2U

― Instrument cluster terminal 1L

• Is the voltage B+?

|

Yes

|

Go to Step 13.

|

|

No

|

If terminal 2U voltage is not B+:

• Go to the next step.

If terminal 1L voltage is not B+:

• Go to Step 7.

|

|

6

|

INSPECT INSTRUMENT CLUSTER POWER SUPPLY CIRCUIT FOR OPEN CIRCUIT AND SHORT TO GROUND

• Switch the ignition to off.

• Disconnect the negative battery cable.

• Inspect the ESCL 15 A fuse and BTN1 50 A fuse.

• Is there any malfunction?

|

Yes

|

If the fuse is blown:

• Repair or replace the wiring harness for a possible short to ground.

• Replace the fuse.

If the fuse is deterioration:

• Replace the fuse.

Go to Step 13.

|

|

No

|

Repair or replace the wiring harness for a possible open circuit, then go to Step 13.

|

|

7

|

VERIFY MALFUNCTIONING LOCATION

• Verify that the instrument cluster connector is disconnected.

• Measure the voltage at the ignition relay (IG1_STAB) terminal D (wiring harness-side).

• Is the voltage B+?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 9.

|

|

8

|

INSPECT IGNITION RELAY (IG1_STAB)

• Switch the ignition to off.

• Disconnect the negative battery cable.

• Remove the ignition relay (IG1_STAB).

• Inspect the ignition relay (IG1_STAB).

• Is there any malfunction?

|

Yes

|

Replace the ignition relay (IG1_STAB), then go to Step 13.

|

|

No

|

Repair or replace the wiring harness between ignition relay (IG1_STAB) and instrument cluster.

Replace the fuse if necessary, then go to Step 13.

|

|

9

|

INSPECT DC-DC CONVERTER CONNECTOR AND TERMINALS

• Switch the ignition to off.

• Disconnect the negative battery cable.

• Disconnect the DC-DC converter connector.

• Inspect the connector for poor connection (such as damaged/pulled-out pins, and corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector or terminals, then go to Step 13.

|

|

No

|

Go to the next step.

|

|

10

|

INSPECT WIRING HARNESS BETWEEN DC-DC CONVERTER AND IGNITION RELAY (IG1_STAB) FOR SHORT TO GROUND

• Verify that the DC-DC converter connector is disconnected.

• Inspect for continuity between ignition relay (IG1_STAB) terminal D (wiring harness-side) and body ground.

• Is there continuity?

|

Yes

|

Repair or replace the wiring harness for a possible short to ground.

Replace the fuse if necessary, then go to Step 13.

|

|

No

|

Go to the next step.

|

|

11

|

INSPECT WIRING HARNESS BETWEEN DC-DC CONVERTER AND IGNITION RELAY (IG1_STAB) FOR OPEN CIRCUIT

• Verify that the DC-DC converter connector is disconnected.

• Inspect for continuity between DC-DC converter terminal K (wiring harness-side) and ignition relay (IG1_STAB) terminal D (wiring harness-side).

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness for a possible open circuit.

Replace the fuse if necessary, then go to Step 13.

|

|

12

|

INSPECT DC-DC CONVERTER

• Inspect the DC-DC converter.

• Is there any malfunction?

|

Yes

|

Replace the DC-DC converter, then go to the next step.

|

|

No

|

Go to the next step.

|

|

13

|

VERIFY TROUBLESHOOTING COMPLETED

• Make sure to reconnect all disconnected connectors.

• Reconnect the negative battery cable.

• Clear the DTC from the instrument cluster using the M-MDS.

• Perform the instrument cluster DTC inspection using the M-MDS.

• Is the same DTC present?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the instrument cluster.

Go to the next step.

|

|

No

|

Go to the next step.

|

|

14

|

VERIFY THAT NO OTHER DTCs ARE PRESENT

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

DTC troubleshooting completed.

|