|

1

|

INSPECT IG1 RELAY No.1

• Switch the ignition off.

• Disconnect the negative battery terminal.

• Remove the IG1 relay No.1.

• Inspect the IG1 relay No.1.

• Is the IG1 relay No.1 normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the IG1relay No.1, then go to Step 8.

|

|

2

|

INSPECT PCM DTC

• Perform the PCM DTC inspection using the M-MDS.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

Go to the next step.

|

|

3

|

BATTERY INSPECTION

• Is the battery normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace or charge the battery.

Then go to Step 8.

|

|

4

|

INSPECT GENERATOR

• Is the generator normal?

|

Yes

|

Go to the next step.

|

|

No

|

• Replace the generator, then go to Step 8.

|

|

5

|

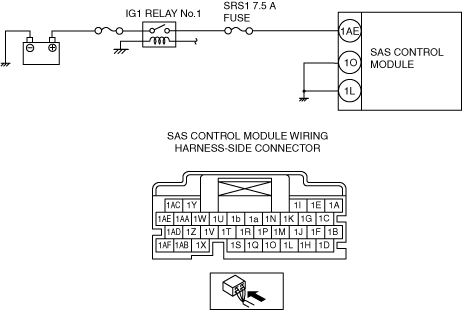

FUSE INSPECTION

• Switch the ignition off.

• Remove the SRS1 7.5 A fuse.

• Is the fuse normal?

|

Yes

|

Go to the next step.

|

|

No

|

If the fuse is blown:

• Refer to the wiring diagram and verify whether or not there is a common connector between SRS1 7.5 A fuse and SAS control module terminal.

If there is a common connector:

-

― Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

― Repair or replace the malfunctioning part.

If there is no common connector:

-

― Repair or replace the wiring harness which has a short to ground.

• Replace the fuse.

If the fuse is damaged:

• Replace the fuse.

Then go to Step 8.

|

|

6

|

INSPECT WIRING HARNESS BETWEEN SAS CONTROL MODULE AND IG1 RELAY No.1

-

Warning

-

• Handling the component parts improperly can accidentally operate (deploy) the air bag module, which may seriously injure you. Read the service warnings/cautions and the workshop manual before handling the air bag system components.

• Install the SRS1 7.5 A fuse.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off or on).

• Measure the voltage at the following terminal (wiring harness-side).

-

― SAS control module terminal 1AE

-

Note

-

• Measure the voltage while shaking the wiring harness between the SAS control module and IG1 relay No.1.

• Is the voltage 8.1–17.9 V?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between SAS control module terminal and IG1 relay No.1 terminal.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit or short to ground.

• Replace the malfunctioning part.

If there is no common connector:

• Replace the wiring harness which has an open circuit or short to ground.

Go to Step 8.

|

|

7

|

INSPECT SAS CONTROL MODULE CIRCUIT FOR OPEN CIRCUIT

• SAS control module connectors are disconnected.

• Switch the ignition off.

• Inspect for continuity between the following terminals (wiring harness-side) and body ground.

-

― SAS control module terminal 1O

― SAS control module terminal 1L

-

Note

-

• Inspect for continuity while shaking the wiring harness between the SAS control module and body ground.

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between SAS control module terminal and body ground.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Replace the malfunctioning part.

If there is no common connector:

• Replace the wiring harness which has an open circuit.

Go to the next step.

|

|

8

|

PERFORM SAS CONTROL MODULE DTC INSPECTION

• Connect the SAS control module connectors.

• Reconnect all disconnected connectors.

• Switch the ignition ON (engine off or on).

• Are the same Pending DTCs present?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the SAS control module.

|

|

No

|

DTC troubleshooting completed.

|