1. Remove the battery and battery tray. (See BATTERY REMOVAL/INSTALLATION [L3, AJ (3.0L Duratec)].)

2. Remove the front wheel and tire (RH). (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

3. Remove the splash shield.

4. Drain the engine coolant. (See ENGINE COOLANT REPLACEMENT [L3].)

5. Drain the ATF. (ATX model) (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [GF4AX-EL].)

6. Drain the transaxle oil. (MTX model)

7. Remove the air cleaner, intake air duct, brake vacuum hose, accelerator cable, and bracket. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [L3].)

8. Remove the front bumper. (See FRONT BUMPER REMOVAL/INSTALLATION.)

9. Remove the cooling fan component. (See COOLING FAN MOTOR REMOVAL/INSTALLATION [L3].)

10. Disconnect the heater hose from the body.

11. Disconnect the upper radiator hose from the water outlet.

12. Disconnect the plastic fuel hose from the fuel distributor. (See Fuel Line Safety Procedure) (See Fuel Leakage Inspection.) (See QUICK RELEASE CONNECTOR REMOVAL/INSTALLATION [L3].)

13. Disconnect the vacuum hose of the purge solenoid valve from the intake manifold.

14. Remove the ATF filler tube and selector cable.(ATX model)

15. Remove shift cable. (MTX model)

16. Disconnect the clutch pipe. (MTX model)

17. Disconnect the PCM connector. (See PCM REMOVAL/INSTALLATION [L3].)

18. Disconnect the wiring harnesses.

19. Remove the transverse member. (See FRONT CROSSMEMBER REMOVAL/INSTALLATION.)

20. Disconnect the front drive shaft. (See FRONT DRIVE SHAFT REMOVAL/INSTALLATION.)

21. Disconnect the propeller shaft on the transfer side.(4WD)

22. Remove the air guide plate. (See TRANSFER REMOVAL/INSTALLATION [GF4AX-EL].)

23. Remove the front pipe. (See EXHAUST SYSTEM REMOVAL/INSTALLATION [L3].)

24. Remove the drive belt. (See DRIVE BELT REPLACEMENT [L3].)

25. Disconnect the lower radiator hose from the radiator.

26. Disconnect the oil hose. (ATX model) (See OIL COOLER REMOVAL/INSTALLATION [GF4AX-EL].)

27. Remove the A/C compressor with the pipes still connected.

28. Remove the P/S oil pump. Position the P/S oil pump out of the way with the hoses and pipes still connected. (See POWER STEERING OIL PUMP REMOVAL/INSTALLATION [L3].)

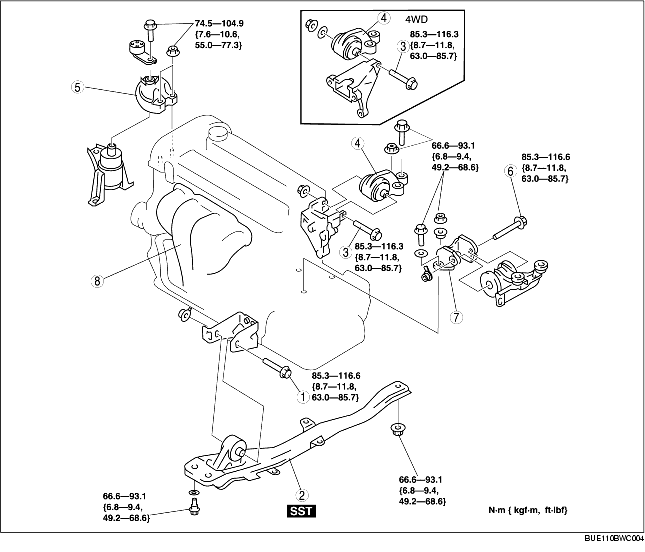

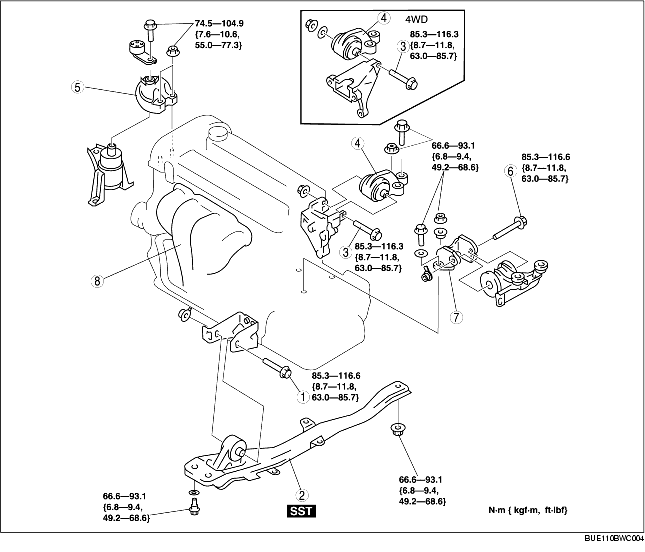

29. Remove in the order indicated in the table.

30. Install in the reverse order of removal.

31. Start the engine, and inspect and adjust the following:

|

1

|

No. 2 engine mount through bolt

|

|

2

|

Engine mount member, No. 2 engine mount rubber (See Engine Mount Member, No. 2 Engine Mount Rubber Removal Note.) (See Engine Mount Member, No. 2 Engine Mount Rubber Installation Note.)

|

|

3

|

No. 1 engine mount through bolt

|

|

4

|

No. 1 engine mount rubber

|

|

5

|

No. 3 engine mount bracket (See No. 3 Engine Mount Bracket Removal Note.) (See No. 3 Engine Mount Bracket Installation Note.)

|

|

6

|

No. 4 engine mount through bolt

|

|

7

|

No. 4 engine mount bracket (See No. 4 Engine Mount Bracket Installation Note.)

|

|

8

|

Engine, transaxle

|

1. Secure the engine using the SSTs.

2. With the SSTs still set, remove the engine mount member and No. 2 engine mount rubber.

1. Secure the engine and transaxle using an engine jack and attachment.

2. Remove the SSTs.

1. Secure the engine and transaxle using an engine jack and attachment.

2. Install the No. 4 engine mount bracket to the transaxle and temporarily tighten the bolts and nuts.

3. Temporarily tighten the No. 4 engine mount rubber and bracket through bolt.

4. Tighten the No. 4 engine mount bracket bolts, nuts, and through bolt in the order as shown in the figure.

1. Tighten the No. 3 engine mount bracket installation stud bolts.

2. Install the No. 3 engine mount bracket and temporarily tighten.

3. Tighten the No. 3 engine mount bracket bolt and nuts in the order shown in the figure.

4. Secure the engine using the SSTs.

5. Remove the engine jack.

1. Install the No. 1 engine mount rubber to the crossmember and temporarily tighten.

2. Tighten the No. 1 engine mount through bolt.

1. Tighten the engine mount member bolts and nut.

2. Remove the SSTs.

3. Properly tighten the No. 1 engine mount rubber bolts and nut.

4. Tighten the No. 2 engine mount through bolt.